ICI Caldaie S.p.A

- Home

- Companies

- ICI Caldaie S.p.A

- Products

- ICI-Caldaie - Model ECS72 - Ecovapor

ICI-Caldaie - Model ECS72 -Ecovapor

Integrated system for steam production: ECOVAPOR ECS72 consists of a series of equipment, assembled and electrically and hydraulically tested at our facility, aimed at ensuring the operation without a continuous supervision by a qualified operator for 72 hours.

Most popular related searches

vertical multistage centrifugal pump

shut-off valve

multistage centrifugal pump

globe valve

non-return valve

pressure monitoring system

ball valve

conductivity probe

solenoid valve

compressed air

- Design pressure: 12 bar

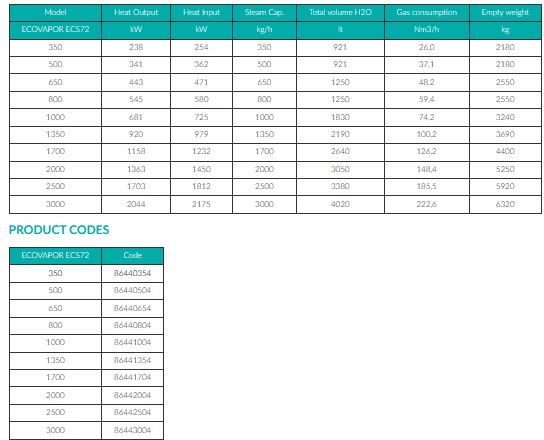

- Heat output: 238 ÷ 2044 kW

- Steam capacity: 350 ÷ 3000 kg/h

- Efficiency: > 94,0 %

- NOx emissions: <70 mg/kWh

- Accessories on the steam side, including:

- Steam outlet globe valve

- spring safety valve (no.2 standard valves only for Ecovapor 2500 model)

- level indicator with direct reflection

- shut-off valve groups and drain indicator

- Integrated economiser consisting of:

- 2 check thermometers

- 1 pressure gauge with three-way test valve

- safety valve

- Water delivery unit mounted on boiler support containing:

- 1 vertical multi-stage centrifugal pump suitable for 120° C water with integrated inverter

- 1 shut-off globe valve

- 1 pump suction filter

- 2 non-return valves

- Adjustment and control system allowing:

- Water level adjustment which depends on the actual steam request from the system

- Thermal power adjustment which depends on the actual steam request from the system

- Burner modulation adjustment, for the management of any power between the minimum and maximum limits, for an optimal adaptation to the feed instant request

- Adjustment of frequency and duration of automatic blowdown

- Entry thresholds adjustment depending on the salinity control unit TDS

- Dynamic programming of the boiler operating pressure set-point

- Automatic blow down system unit containing:

- globe valve

- rapid opening drain ball valve, with steel body, pneumatic actuator and return spring equipped with compressed air solenoid valve

- Sample cooler containing:

- AISI 304 barrel with an internal water-cooling coil

- cooling water injection ball valve

- handwheel valve for sample picking

- Pressure monitoring instrumentation manifold, consisting of:

- large dial 3 way test valve manometer

- fail safe manual reset safety pressure switch

- analogue pressure transducer

- Temperature monitoring

- ambient temperature

- flue gas temperature

- Automatic conductivity probe level regulator, consisting of:

- capacitive probe for level control and management

- 1st alarm and burner shut off probe for low level with self-checking

- 2nd alarm and burner shut off probe for low level with self-checking

- high level safety probe

- Connectivity and data logging

- ECOVAPOR management system is certified to manage safety chains, has an expandable control system and has a connectivity system via LAN, WiFi, Modbus, Modem. It is fully equipped with a SIM for the transmission of data.

- This allows the following benefits:

- Register the product in the machine database to facilitate remote service operations.

- Recording of start-up and maintenance operations.

- Connection between the boiler and the other management and control systems.

- Free update of the boiler control software.

- Collection of data on the operating state through external and internal sensors of the plant room and boiler.

- Self-checking and alarm status indications.

- Pneumatic salinity control unit TDS consisting of:

- direct reading conductivity probe in the boiler

- 2 shut-off valves

- pneumatic exhaust valve with compressed air solenoid valve