- Home

- Companies

- Integrity Municipal Systems (IMS)

- Products

- IMS - Fluoride Feed System

IMS - Fluoride Feed System

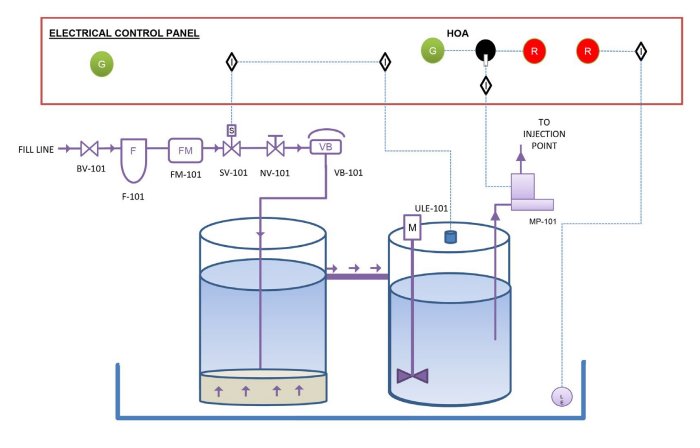

The IMS Fluoride Feed System is designed with separate saturator and solution tanks to assure complete saturation, high reliability, low maintenance, and ease of use. Systems are sized to meet customer requirements.

IMS Provides Packaged Fluoride Feed Systems (Pre-Assembled, Piped, Wired, and Factory Tested).

The IMS design – which includes an upflow saturator and a separate solution storage tank – sets the IMS Fluoride Feed System apart from the competition. Water is introduced and distributed at the bottom of the upflow saturator and passes through the sodium fluoride salt resulting in a saturated sodium fluoride solution at the top. This solution passes through an overflow to the separate solution storage tank and is then metered from there to an injection point.

This secondary containment supplemented with a high water alarm eliminates the need for separate system containment. Finally, the IMS Fluoride Feed System’s chemical metering pump can integrate with facility SCADA control and operation.

Completely Packaged System

- factory plumbed, wired, assembled, and tested

Plug-and-Play Installation

- compact, known footprint and input requirements

Upfow Saturator and Solution Storage Tank

- reduces plugging of metering pump, cleaning requirements, and maintenance

Fully-Contained

- the entire packaged system resides in a secondary, alarmed containment vessel.

- Potable soft water supply to system: 1 to 2 gpm at 20 psig

- Saturated Sodium Fluoride solution to injection point

- 110V, single phase, 15 amp power supply to control panel

- 4 to 20 mA signal metering pump control (if available)

- Low low (LL) and high high (HH) alarm from fluoride analyzer to control panel

- Superior Upflow Saturator Design

- Separate Saturator and Solution Tank

- Modular, Pre-assembled, Factory Piped, Wired, and Tested System with Compact Design (5.5’L x 5.0’H x 2.5’W)

- Custom Designed System

- Fully Contained System

- Saturator Automatic Operation

- Integrated Control Pane

- Assures complete saturation, high degree of reliability, and very low maintenance requirements

- Reduces or eliminates suspended solids in the solution tank and prevents dosing pump from plugging

- Very short installation time and low installation cost

- Reduces capital investment because of easy relocation, if desired

- Requires small footprint for installation

- Factory tested before delivery, significantly reducing system start-up time (~2 hrs)

- Meets site specific requirement and provides desired features

- Eliminates any risk of Sodium Fluoride solution entering floor drains

- Level controls are pre-set to allow smooth Saturator operation

- Single point of connection by installer