Integrity Municipal Systems (IMS) products

Wet Emergency Chlorine Scrubber Systems

IMS - Model EVS-150 - Wet Emergency Chlorine Scrubber Systems

The EVS-150 emergency chlorine scrubber is a multi-stage wet scrubber system designed to treat chlorine vapors from a bank of 1501b (70kg) chlorine cylinders, at leak rates of 28 Ibs/min or more, exceeding the requirement of the Uniform Fire Code. The EVS-150 system is designed to maintain negative pressure in the chlorination and chlorine storage rooms, while limiting the atmospheric release of chlorine to less than 1 ppm. The factory-assembled EVS-150 system is very compact, with low profile suitable for either indoor or outdoor installation. It is designed by Roop Jain, the founder of RJ Environmental, and a renowned leader and innovator in chlorine scrubber technology for the last 25 years.

Carbon Odor Control Systems

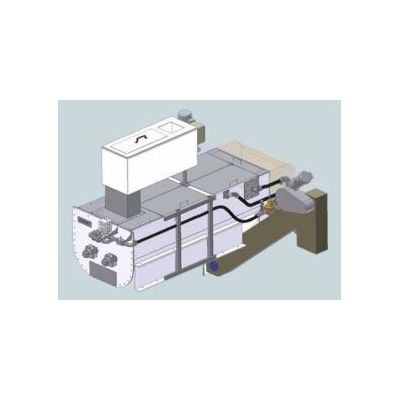

IMS - Model MCS Series - Skid-Mounted Carbon Adsorber

The IMS Model MCS carbon adsorber is a once-through activated carbon odor removal system designed to treat hydrogen sulfide (H2S) & organic odors (VOCs) found in municipal wastewater collection systems and treatment processes. The MCS is a factory-assembled, skid-mounted odor control system complete with exhaust fan, damper, interconnecting ductwork, vessel, activated carbon media and local control panel. All components are mounted, piped, and wired on an epoxy coated carbon steel skid. System is designed (or continuous and automatic operation as well as manual operation as required.

Dry Emergency Chlorine Scrubbers

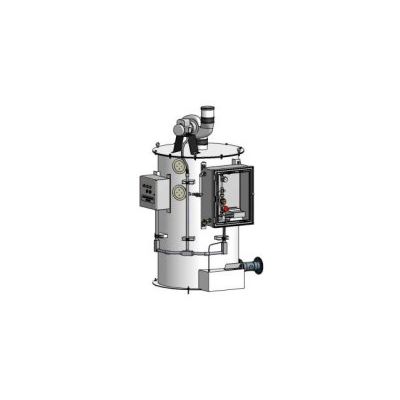

IMS - Model RJD-2000 - Dry Media Emergency Chlorine Scrubber System

The RJD-2000 emergency chlorine scrubber is the next generation in emergency chlorine scrubber technology. It uses a new high capacity, non-hazardous dry adsorbent media to absorb up to 1-Ton of chlorine vapor, at leak rates up to 78 lbs/min as required by the Uniform Fire Code. The RJD-2000 system is designed to maintain negative pressure in the chlorination and chlorine storage rooms, while limiting the atmospheric release of chlorine to less than 1 ppm. The factory-assembled RJD-2000 system is the most compact dry chlorine scrubber available, with low profile suitable for either indoor or outdoor installation. It is designed by Roop Jain, the founder of RJ Environmental, and a renowned leader and innovator in chlorine scrubber technology for the last 25 years.

IMS - Model RJD-150 - Dry Media Emergency Chlorine Scrubber System

The RJD-150 emergency chlorine scrubber is the next generation in emergency chlorine scrubber technology. It uses a new high capacity, non-hazardous dry adsorbent media to absorb up to 150 lbs (70 kg) of chlorine vapor, at leak rates up to 78 lbs/min as required by the Uniform Fire Code. The RJD-150 system is designed to maintain negative pressure in the chlorination and chlorine storage rooms, while limiting the atmospheric release of chlorine to less than 1 ppm.

Biological Odor Control Systems

IMS - Model I-BOx™ - Biological Odor Control System

The IMS l-BOx™ Series odor control system {Patent Pending) is an advanced two-stage biological system that provides ooint source odor control. The first stage is a biological reactor where bacteria are used to oxidize hydrogen sulfide (H2S) and organic sulfur compounds. The second stage uses activated carbon to remove residual H2S and organic odors.

Lime Slaker System

IMS - Model A-758 - Lime Slaking System

Lime is one of the most common and economical chemicals used in the water and wastewater treatment process. The cost of commercial bulk hydrated lime or prepared lime slurry solutions, however, becomes prohibitive for installations requiring a continuous, high volume supply, typically greater than 45 kgs/hr (100 lbs/hr). To help alleviate this cost, on-site slaking or hydration is the ideal solution. The Series A-758 lime slaker provides for reliable, efficient slaking of various grades of quicklime (CaO) at a substantial savings over other slaking methods. Through the pioneering use of paste-type slaking technology, the Series A-758 lime slaker consistently produces a more reactive lime slurry requiring less energy and less operator attention. The compact size and flexible configuration make this pre-engineered system ideal for new and retrofit installations.

IMS - Model Series 31-165 - Microprocessor Controlled Weighbelt Feeder

The Series 31-165 microprocessor controlled weighbelt feeder controls the feed rate of dry chemicals with an accuracy as low as

0.25% of set rate. Its accuracy and instantaneous response to feed rate changes and variations in material density provide tight control of chemical usages and minimize waste. The controller can provide information about chemical application rate for record keeping or inventory control. The Series 31-165 weighbelt feeder is ideal for industrial and municipal water and wastewater treatment systems or for systems treating industrial process water.

IMS - Model A-758 Plus - Lime Slaking System

The A-758 Plus Lime Slaker system provides reliable, efficient slaking of various grades of quicklime (CaO) at a substantial savings over other slaking methods. Our paste-type lime slaker produces a higher strength and more reactive paste resulting in more efficient use of lime. The resulting higher strength slurry reduces wasted lime and associated costs, ensuring treatment objectives are efficiently met. For over 40 years, we have pioneered the design and application of paste-type lime slakers. Our recent developments to the lime slaker technology bring new features which extend equipment life, reduce maintenance costs, and improve control and reliability.

Chemical Feed Systems

IMS - Fluoride Feed System

The IMS Fluoride Feed System is designed with separate saturator and solution tanks to assure complete saturation, high reliability, low maintenance, and ease of use. Systems are sized to meet customer requirements.

IMS - Hydrofluosilicic Acid Feed System

The IMS Hydrofluosilicic Acid Feed System provides safe storage and accurate dosing of Hydrofluosilicic Acid, in a fully contained, pre-assembled skid. The packaged system is pre-wired and piped with local instrumentation and controls.