- Home

- Companies

- Integrity Municipal Systems (IMS)

- Products

- IMS - Model A-758 Plus - Lime Slaking ...

IMS - Model A-758 Plus -Lime Slaking System

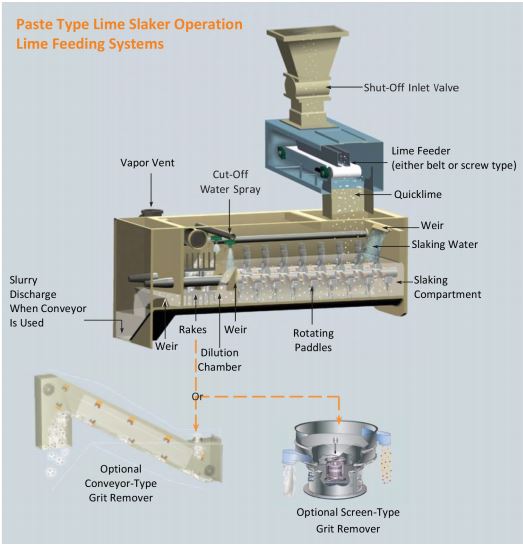

The A-758 Plus Lime Slaker system provides reliable, efficient slaking of various grades of quicklime (CaO) at a substantial savings over other slaking methods. Our paste-type lime slaker produces a higher strength and more reactive paste resulting in more efficient use of lime. The resulting higher strength slurry reduces wasted lime and associated costs, ensuring treatment objectives are efficiently met. For over 40 years, we have pioneered the design and application of paste-type lime slakers. Our recent developments to the lime slaker technology bring new features which extend equipment life, reduce maintenance costs, and improve control and reliability.

- More reactive lime slurry improves efficiency, reduces lime costs and ensures treatment objectives are met

- More efficient; external heat souce not required

- Reliable performance and robust construction reduce operator attention and lower maintenance costs

- ƒFaster slaking improves responsiveness, making it easier to control over a wider range

- Smaller footprint and flexible configuration make installation simple

- Superior Paste-Slaking Process : Utilizing a low water-to-lime rate (2:1), the A-758 Plus unit slakes lime as a paste which provides a number of benefits over the more traditional 4:1 or slurry slaking process. This includes lower power consumption, faster slaking, a smaller footprint and, most importantly, a more reactive lime slurry solution. In addition, the A-758 Plus incorporates innovative controls to produce consistent and reliable paste concentrations.

- Less Power : The 2:1 paste slaking process generates its own heat from the hydration heat of reaction. This avoids the need and expense of an external heat source, internal heat exchangers, and temperature control systems. Paste slaking combined with slow speed mixing conserves energy by 50% or more compared to other lime slaking systems.

- Faster Slaking : Fast slaking is accomplished due to the low water content of the paste. Heat generated by the hydration completes the slaking process in approximately five minutes. This short retention time provides efficient start-stop or batching operation and the ability to make rapid changes in lime concentration when required. The simplified process also reduces maintenance costs.

- Smaller Footprint : Faster slaking is more responsive to changes in demand, easier to control and offers a wider range of operation (20:1 turndown). Faster slaking also accounts for a compact size which saves on valuable floor space that offers installation flexibility

- More Reactive Lime Slurry : The intense heat generated by the 2:1 slaking ratio subjects the quicklime to thorough steam penetration. The resulting internal pressure promotes the fracturing of the quicklime into smaller, more highly reactive particles. This means more surface area for more efficient lime usage to ensure treatment objectives are met confidently and with less waste.

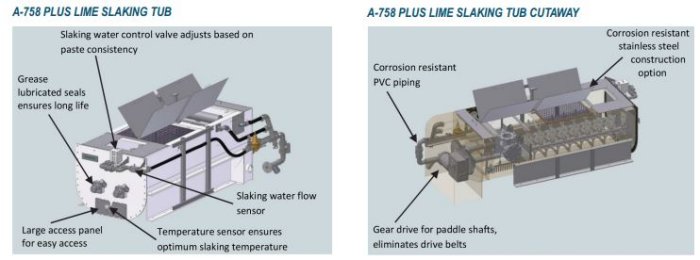

- Consistent and Reliable Slaking : The A-758 Plus incorporates automatic adjustment of the slaking water addition by measuring the torque on the paddle mixer shaft. The result is precise and continuous control of paste consistency without the need for operator intervention.

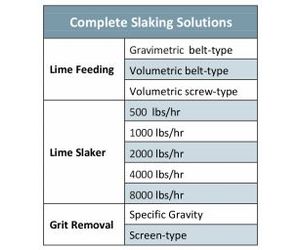

Lime slaking systems require more than just the slaker. We offer complete solutions including lime feeding and grit removal technologies which are an integral part of the lime slaking process. Our lime feeding technologies include gravimetric or volumetric belt-type and screw-type systems. Our grit removal technologies include specific gravity classification and screen-type systems.

Extending life and reducing maintenance costs result from new and improved engineering design

- Stainless steel construction option prevents corrosion for long life, reducing maintenance costs

- Gear drive eliminated belts, which need to be replaced, reducing maintenance costs

- Bearings and seals upgraded for extended life, reducing maintenance costs

- Large access panel makes clean-out easier ensuring operator safety. reducing maintenance costs

- Corrosion-resistant PVC piping extends life and reduces maintenance costs

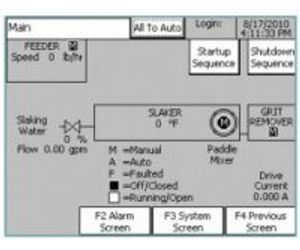

- Start-up and shut down sequence includes automatic flush cycle, reducing operator cleaning and maintenance costs

- PLC controls with graphics touch screen operator interface provides a simple, flexible and intelligent operation

- ƒFlow and temperature instrumentation, verifies correct operation

- ƒInnovative paste consistency measurement and control provides reliable and consistent paste concentration

Water and quicklime (CaO) are fed into the slaker mixing compartment at an approximate 2:1 ratio. The lime is metered by either a gravimetric weigh belt feeder or a volumetric screw or belt-type feeder. Controlling the lime feedrate determines the output of the slaker system. The water flow is automatically controlled based on the desired paste concentration.

In the slaking compartment, two intermeshing paddle shafts, rotating in counter directions, mix the quicklime and water into a paste-type composition, controlled by the torque valve to the 2:1 slaking ratio. Any variation in the paste consistency caused by vapor loss, lime quality or size fluctuations, or changes in the lime feed rate, results in a different torque load on the paddle shafts. This causes the PLC to adjust the water flow to maintain the desired paste consistency.

The paste and entrained inert grit moves forward in a plug-flow fashion. After approximately five minutes, the completely slaked lime paste flows over a weir into the dilution compartment. Here water nozzles direct a cut-off spray to dilute the paste into a lime slurry at an approximate 4:1 concentration. This also releases the grit from the lime paste so that it can be removed. Two sets of rotating rakes keep the lime in suspension and help move the grit to the grit separator.

Dust and steam, generated by the exothermic reaction of the lime and water, are drawn off by an integral, water operated vapor-dust arrestor. The steam and dust are condensed and returned to the dilution compartment. Excess steam and water vapor are vented outside of the slaker.

A low water pressure switch in the inlet water piping is designed to stop the lime feeder when the supply pressure falls below the minimum operating requirement. This avoids heat build-up due to insufficient slaking water. The feeder automatically restarts when the pressure is restored.

The paste-type lime slaker is ideally suited for all types of control systems. In a continuous process, slaker operation remains constant. Lime slurry is continuously discharged while the lime feed rate can be varied to account for flow or process variations. Lime can be gravity flow, directly to the point of application without the need for costly slurry handling equipment. For batching applications, the slaker system can be automatically stopped and started. The low water-to-lime ratio ensures a fast start-up to bring the slaker on line quickly. Both long-term (> 8 hours) and short-term (< 8 hours) shutdown modes are operator selectable.