- Home

- Companies

- ANTICOR Sp. z o.o.

- Products

- Bristle Blaster - Model MBX Series - ...

Bristle Blaster - Model MBX Series -In-Line Drive Unit

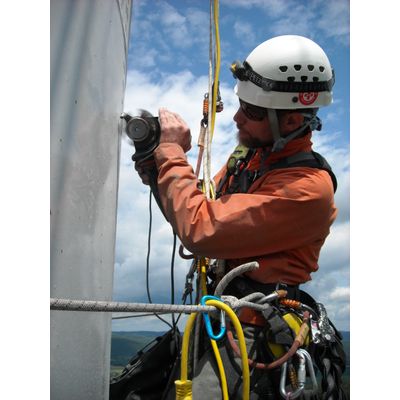

The Bristle Blaster Industrial Pneumatic is an IN-LINE drive unit which is distinguished by patented innovations (the patented air cooling system increases the service life of the flexible Bristle Blaster belts, the patented Accelerator bar is the basis for achieving roughnesses on steel or stainless steel and other materials (40- 120 µm) as well as surface cleaniness according to DIN EN ISO 8501-1 SA 2.5 / SA 3, as are also achieved for conventional blasting.) The special designed gear reduction increases the torque at 2,300 rpm. The low operating speed of 2,300 rpm and the light construction (1.2 kg) ensure a high degree work safety and easy, flexible handling. The IN-LINE design of the Bristle Blaster Industrial Pneumatic allows the highest possible efficient operation in difficult to reach areas and in places where blasting is not possible, is not allowed or is not economical.

The Bristle Blaster Industrial Electric is an IN-LINE drive unit which is distinguished, above all, by the patented Accelerator bar. This innovation is the prerequisite for achieving roughnesses on steel/stainless steel and other materials (40- 120 µm) as well as surface cleaniness according to DIN EN ISO 8501-1 SA 2.5 / SA 3, as are also achieved for conventional blasting. The low operating speed of 2,300 rpm and the light construction (2.3 kg) ensure a high degree work safety and easy, flexible handling. The IN-LINE design of the Bristle Blaster Industrial Electric allows the highest possible efficiency of operation in difficult to reach areas and in places where blasting is not possible, is not allowed or is not economical.

Advantages and Performance of the MBX Bristle Blaster Technology

- Removal of corrosion, mill scale and defunct protective coatings with a surface cleanliness similar to SA 2.5 (NACE No.2/SSPC-SP10 to SA 3 (NACE No.1/SSPC-SP5) = Restores surface to DIN EN ISO 8501-1 / SA 2.5 to SA 3.

- Surface texture / Anchor profile up to 120µm (Rz) / 4.72 mils = Roughness capability from 40- 120µm Rz / 1.57 - 4.72mils . Also in areas where blasting is not permitted. Applies for non-ferrous metals as well.

- Improved integrity of treated surfaces = Generates compressive residual stress along treated surfaces providing crack growth resistance, improved fatigue life, and improved corrosion resistance.

- Negligible heat generation = Surfaces free of thermal damage and/or heat marking.

- Eco Friendly = GREEN surface preparation, does not use/produce hazardous materials. Low energy requirements.

- Simple and Economical = Eliminates the need for complex and costly abrasive blast equipment. Benefits include: no recycling costs for contaminated blasting abrasives, avoidance of major transport costs of the blasting abrasives, rapid commissioning, continuous in-service operation due to ergonomic low system vibration (Vibration test).

- Safety: low vibrations (vibration test), continuous use of the tool for a number of hours per day is possible due to the low levels of vibration from the tool. ((there is no risk to operator health resulting from Hand-Arm Vibration Syndrome (HAVS)), no costly protective clothing required (it is not necessary to wear costly protective clothing, as is needed when blasting, due to the low operation speed of the tool of 2300 rpm. Only safety glasses, gloves and a face mask are required for safe operation), a light and ergonomic design allows continuous operation with minimal fatigue, low noise levels (sound pressure level (SPL) of a maximum of 83.2 dB(A) is reached during operation. Compare this to other rust removal systems sometimes capable of achieving a sound pressure level in excess of 95db(A)), low levels of flying sparks (ATEX conformity) for MBX® Bristle Blaster® Pneumatic Tool according Ex II 2G c IIA T4 X.