- Home

- Companies

- Triple/S Dynamics, Inc. a KM Global ...

- Products

- Triple S Dynamics - Model Slipstick - ...

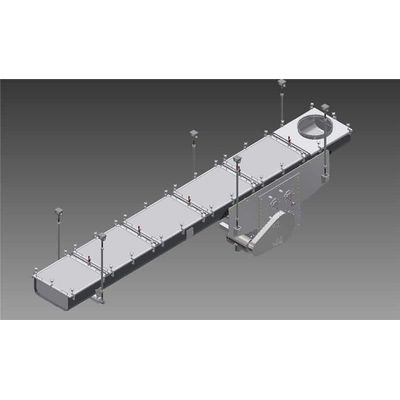

Triple S Dynamics - Model Slipstick -Industrial Vibratory Conveyor

Triple/S Dynamics pioneered horizontal motion conveying in the early 1970’s. The first units were sold into foundry and heavy metal operations. The Slipstick’s reliability in these harsh environments is unmatched. Some of the original 1970’s units are still in operation today. The Slipstick® Horizontal Motion Conveyor is recognized for its non-vibratory conveying motion and enviable record of low maintenance, high reliability performance. The slow forward-quick return motion is independent of natural frequency, springs and tuning.

Highly effective for conveying bulk granulator, heavy or powdered products, the Slipstick’s gentle motion practically eliminates dusting and spillage, and wear on the pan is reduced with the lack of vertical, impacting motion.

The Slipstick Industrial Conveyor is at work in almost every industry around the globe – any industry that needs vibratory conveyors for bulk material handling.

The key to horizontal motion conveying is the action of the conveyor upon the inertia of the conveyed materials. During the slow advance of the conveyor’s cycle, material is at a relative rest on the conveying surface. The quick return segment of the cycle gently slides the conveying surface under the material bed. Repeating this cycle 200 – 300 times per minute serves to smoothly convey the material over forty feet per minute along the length of the conveying surface. This gliding of the product along the seamless one-piece formed conveyor pan discourages build-up of materials on the surface and typically scours the pan clean so there’s less time required between production cycles for cleaning. At the same time, the horizontal motion conveyor offers a much higher level of mechanical simplicity than either screw or drag conveyors.

This mechanical simplicity offers a conveyor that requires significantly less maintenance. In addition, with no chains, screws, sprockets, rollers, idlers, or other moving parts located outside of the sealed and guarded drive unit, the horizontal motion conveyor is intrinsically safer for operating and maintenance personnel. The reliability can be an order of magnitude above those other types of conveyors as well. Based on its unique design that features a self-contained drive unit that has no outbound moving parts, the horizontal motion conveyor is virtually maintenance-free. And based on its relatively slow rotational speed, a typical drive unit will usually deliver more than ten years of life between service intervals, with only periodic lubrication required. Finally, since these conveyors utilize no springs or counterweights, they do not require the periodic tuning that is part of an ongoing maintenance program for conventional vibrating systems.

This horizontal motion conveyor design offers a number of advantages over conventional vibrating conveyors, belt conveyors, pneumatic conveyors, screw conveyors, and drag conveyors often used in bulk handling applications. Compared to conventional vibrating conveyors, which are usually powered by springs and convey material through the impact on the conveyed material, the horizontal motion conveyor provides gentle transportation, longer lengths, reversibility and many features other types of bulk handing conveyors can’t provide.

Based on its many advantages over conventional vibratory conveyors, the horizontal motion conveyor is increasingly being utilized in a wide range of powder and bulk handling applications. There are a number of demanding applications where the special attributes of the horizontal motion conveyor can be significant including:

- Crushed ores: the combination of abrasion-resistant pans, the ability to accommodate large, heavy volumes, and thorough dust containment characteristics make horizontal motion conveyors a practical choice for this demanding application.

- High temperature materials: with no springs to fail, the horizontal motion conveyor can operate in a wide range of extreme temperatures. In certain applications, air or water cooling systems have been used with horizontal motion conveyors to reliably handle materials up to 1700 F.

- Pharmaceuticals: because the horizontal motion of these conveyors naturally eliminates product sticking and the creation of fines and other residual materials, they are ideally suited to meeting the most demanding requirements of sanitation and cleanability.

- Hazardous or toxic materials: based on the total isolation of conveyed material that can be achieved with enclosed horizontal motion tube conveyors, hazardous and/or toxic materials can be transported without fear of escaping fugitive dust/fumes.