- Home

- Companies

- Ion Exchange (India) Ltd.

- Products

- Ion-Exchange - Continuous Sand Filter

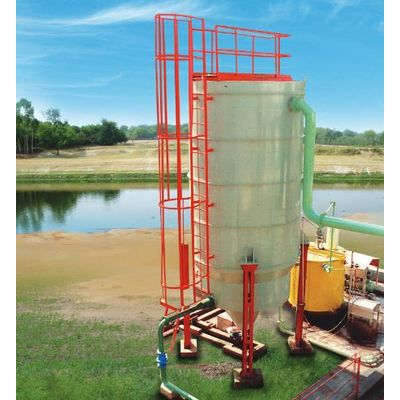

Ion-Exchange - Continuous Sand Filter

Ion Exchange offers a continuous upflow filter, which can filter influent containing up to ten times more dirt than a conventional filter. This revolutionary sand filter does not require to be backwashed to keep the filter bed clean as the sand bed is continuously cleaned and regenerated by internal recycling. This ensures uninterrupted operation without stopping for backwash.

The continuous operation results in a constant and low pressure drop. Maximum clean filtrate is assured since the filter bed always contains a certain amount of solids which improve filtration. This mode of operation also enables the filter to accept a highly polluted flow with high efficiency. The unique cleaning method means backwash water storage tanks and backwash pumps can be dispensed with.

The sand bed of this continuous upflow filter is dirtiest around the feed inlet in the lower part of the filter. The dirty sand is carried from the lower part of the filter through the air lift pump up to the sand washer in the upper part of the filter. The cleaned sand is then returned to the upper layer of the bed. The entire filter bed is thus constantly moving downwards. This continuous action enables it to filter influent containing up to ten times more dirt than a conventional filter.

- Raw water filtration for potable use

- Raw water filtration for industrial process water

- Cooling tower sidestream filtration and make up

- Recycling of white water in pulp and paper industry

- Tertiary treatment of sewage

- Treatment of industrial waste water

- Filtration of water to remove mill scale

- The system is suitably designed for operating at atmospheric pressure.

- Filter shell is in mild steel plate or in RCC construction, depending upon the flow rates and requirements.

- Components like inlet hood, overflow weir, collection vessel and sand distribution cone are in mild steel epoxy coated construction.

- Filter media is graded sand which is suitably selected for the application.

- Air lift pump hose is in natural rubber and clamps are of stainless steel.

- Available in various sizes in steel with flow rates of 2 - 100 m3/h. For higher flow rates, a concrete walled honeycombed structure is used.

- Surface loading depends upon the type of application and varies from 6 m/h to 30 m/h.