- Home

- Companies

- CMV Sharper Finish

- Products

- Finish Rite - Ironer

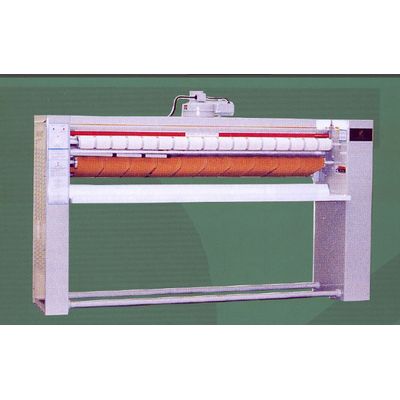

Finish Rite - Ironer

The ironing process of the Finish Rite ironer - and the results - are very similar to careful hand ironing, but considerably faster and easier. The padded pressure roll that applies just the right amount of pressure automatically to smooth out the wrinkles produces the exceptional ironing quality. The surface speed of the automatic feed conveyor is less than the pressure and healed rolls. The result is a gently pulling action that removes wrinkles before the linen is firmly held against the heated roll for drying- Linen to heated roll contact is nearly 420 square inches, offering superior drying capacity. Far more stretching and drying can be done with the Finish Rite than by comparable single roll chest ironers.

Why Iron?

- Unfinished linens can destroy the ambiance of an otherwise well appointed dining or hotel room. "No-Iron" linens were developed primarily for home use, where dryer temperatures and spin cycles can be precisely set and the flatwork can be taken from the dryer in time to preserve an acceptable appearance. This degree of personal attention is not possible, even in the smallest of commercial hundry operations.

- An on-prcmiscs laundry provides a significant dollar savings and is considerably more convenient and flexible than an outside service.

Simplified Operation

- The Finish Rile greatly simplifies ironing. An operator can be trained to use the Finish Rite in a short period of time.

- Linen to be ironed is taken from the washer/extractor and placed on the Finish Rite`s automatic feed conveyor, which guides the linen accurately and at the correct speed to a highly polished, heated finishing roll (excessive moisture might require the linen to be placed in a dryer for a short time prior to ironing).

- After passing over the heated roll, the ironed linen is deposited ou a table conveniently located at the front of the machine. The linen can now be stacked or folded for immediate use.