- Home

- Companies

- JAG Jakob Ltd.

- Products

- JAG - Model PES - Powder Injection ...

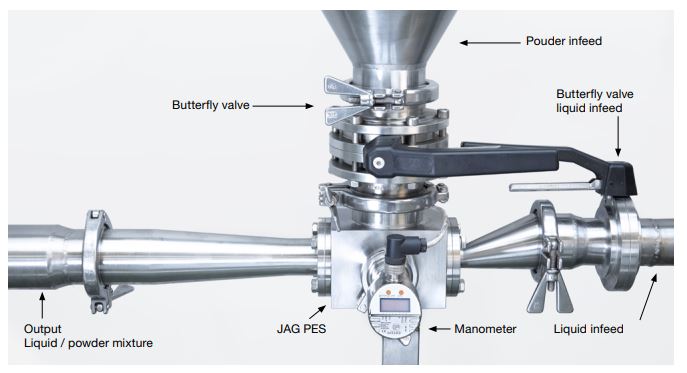

JAG - Model PES -Powder Injection System

The JAG PES injector system has been specially developed and designed for powder solids infeed. Flexibility and interchangeability of the key elements enable all kinds of powder products to be fed into liquid media with the same device. For products which do not flow easily a mechanical discharge device can be integrated. The optimised and adjustable nozzle shape ensures wetting of the powder already in the injector system. The result: homogeneous mixes free from lumps.

- Dust-free power infeed

- No humidity in the powder stock

- High viscosities achievable

- Shorter mixing times

- Good wetting prevents lump formation

- Homogeneous mixing

- High flexibility

- CIP/SIP compatible

For homogeneous, lump-free mixing of powder and liquids

The JAG PES Powder Infeed System was developed to feed powder solids into liquids and works according to the Venturi principle. It is suitable for use under extremely tough conditions in the pharma, biotech, chemical and food industries.

Functional principle

Fluid is pumped into the JAG PES through an infeed cone. A vacuum is generated inside the JAG PES, which draws the solid material into the liquid via the powder line. The adjustable nozzle geometry, accurate powder dosing and recirculation enable lumpfree, highly homogeneous mixing.

JAG PES systems integrated into the process unit can be cleaned either automatically via CIP/SIP or manually thanks to the ease with which they can be disassembled.

A manometer can be connected to the JAG PES.

Benefits and features of the JAG PES Powder Infeed System

- Dust-free powder feed into liquids

- The powder-to-liquid mixing ratio can be Dosed precisely

- No moisture in the powder stock

- High viscosities can be mixed

- Recirculation ensures homogeneous mixing

- Can be fitted directly onto silos, hoppers, containers, settling tanks

- CIP-/SIP-compatible

- Shorter mixing times than with

- Conventional methods

- Easy to disassemble, enabling flexible modification

- Cone, connectors: 1.4435 (316L) with certificate option 3.1

- Surfaces: surfaces in contact with products RA ≤ 0.8 µmw

- Gasket: EPDM (FDA conformity)

- Operate temperature: max. 60ºC

- Pressure range: max. 10 bar

- Throughput liquids: ca. 13 m³/h (water)

- Throughput bulk solids: ca. 1.5 t/h (depending the product)

Dimensions

- Lengh: 480 mm

- Wide: 110 mm

- Powder infeed: ISO DN 65/TC

- Liquid infeed: ISO DN 50/TC

- Liquid output: ISO DN 50/TC

- Measuring pipe: ISO DN 20