- Home

- Companies

- TerraSource Global

- Products

- Jeffrey Rader - Model Mini-Mill - ...

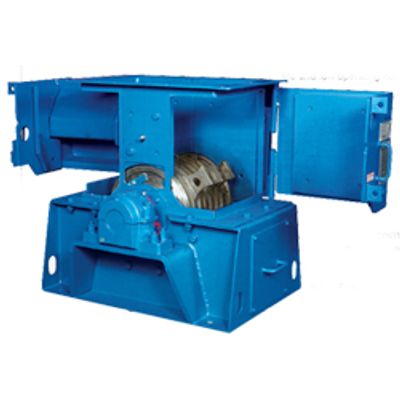

Jeffrey Rader - Model Mini-Mill -Hammermills

The Junior “E”, Mini-Mill™, 30ABE and 34AB models include the same features as Jeffrey Rader’s large hammermills. Jeffrey Rader incorporates hinged swinging doors on our small hammermills–allowing optimum access, while maintaining durability. These units are ideal in moderate volume applications where changing material specifications are required.

Unmatched Versatility

You can use these small-to-medium-sized hammermills in a wide variety of applications. The type of material you are reducing determines the rotor configuration, and the product size you desire determines the screen bar arrangement.

For pulverizing friable materials such as limestone, Jeffrey Rader hammermills come with rectangular swing hammers. For shredding materials such as waste paper, fiberglass mats, or rubber–or when the application requires the machine to run at slow speed–choose rigid hammers.

EZ Access® Technology

The hammermills have been designed with Jeffrey Rader’s exclusive EZ Access technology, which allows safe, fast, and easy access to the hammers, rotor and liners. Now maintenance operators can safely and quickly perform routine maintenance with more safety and ease.

Screen Grates

Jeffrey Rader fabricated screen grates, racks and bars and perforated plate is designed to provide the greatest amount of free open area, allowing the machine to obtain the highest capacity while accurately sizing the material to the specified size. Our screen grates are made of abrasion resistant materials, but can be supplied with other materials depending on the application and sizing requirements.

Heavy-Duty Rotor Design

Our disc-type rotor is assembled on a high-strength, alloy-steel shaft and is mounted in self-aligning spherical roller bearings (Models 30ABE & 34AB) or ball bearings (JR & mini) in rugged steel housings. Rotor discs allow maximum flexibility of hammer arrangements. Jeffrey Rader rotors can setup with three, four, or six rows of hammers for premium efficiency when shredding to a smaller product size.

Hammer Designs

Our hammers are manufactured from our Ultralloy® material to provide the ultimate in performance, long life and low operating costs. The hammers are hard throughout, yet still have the ductility and toughness to withstand high-impact conditions. Where the application requires we have both harder and softer materials to provide the optimal performance and life in the hammers while keeping operating costs to a minimum. In addition to our current material offerings, we are constantly looking at new alloys to improve overall equipment performance.

Our hammers also are available in a variety of shapes from a standard bar hammer to a six-point rigid hammer. The hammer design is based on the application and when combined with the appropriate material will ensure the machine is operating at its maximum efficiency.

Steel Housing

Rolled-steel, structurally reinforced housings ensure long-lasting durability. When properly maintained, the hammermill’s fully-lined interior prevents the housing from wearing on the inside. Doors on the upper housing provide access to the metal trap and the interior of the machine.

Liners

All liners are manufactured from thick abrasion-resistant steel plate to protect against high impacts and normal wear. Liners are drilled, tapped, and bolted from the outside to eliminate bolt heads on the inside where they can wear and break off.

Extended Lower Housing

Lower housing is extended to provide 180° of screen grate area. The extensive screen area reduces operating costs by allowing more open area in the machine, and it effectively discharges the material without causing a re-circulating load. Plus, the instances of plugging (from wet material) are greatly reduced.

Tramp Metal Protection

Jeffrey Rader Model 30ABE & 34AB hammermills include an integral metal trap that effectively collects the odd pieces of smaller tramp metal which can damage your machine. The tramp metal pocket is located in the back of the machine. As tramp metal enters the hammer circle, the hammers lay back and carry the material around to and place it in the metal trap. Metal traps are optional on the Mini Mill.