- Home

- Companies

- TerraSource Global

- Products

- Jeffrey Rader - Model RDS - Disc Screen

Jeffrey Rader - Model RDS -Disc Screen

A heavy duty scalping screen for woodchips, hog fuel and bark. Let Jeffrey Rader recommend a disc screen that’s right for your particular application.

The industry’s number one scalping screen.

When it comes to removing oversized rejects from unscreened wood chips, hog fuel or bark, the Jeffrey Rader Disc Screen is the undisputed workhorse of the industry. With more units in operation than all other suppliers combined, you can depend on Jeffrey Rader to recommend a model that’s right for your particular operation.

Engineered and manufactured to your specific requirements.

The Jeffrey Rader Disc Screen is never supplied “off the shelf”. Based on the individual application, Rader engineers select the ideal disc profile, interface openings and screen size for maximum screening efficiency. Then, using only first quality materials and components, the screen is manufactured under ISO 9001 specifications.

Designed for long service life and ease of maintenance.

Wood chip and hog fuel processing is typically a 24-hour-a-day operation. That’s why you need a screen on which you can depend. The RDS is engineered for rugged, non-stop service with only routine maintenance. When scheduled maintenance is required, all service points and components are easily accessible.

Advantages of the Jeffrey Rader Disc Screen

Efficient resource recovery depends on separating the maximum amount of desireable materials from the raw wastes. To do this, the disc screens are used in many locations in the processing cycle.

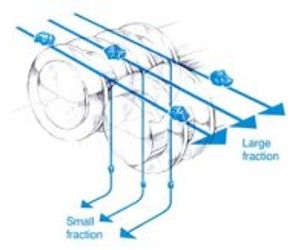

The disc screens separate material particles by allowing the smaller fractions to drop through openings of controlled size. Unlike static screens, however, the Jeffrey Rader disc screen continuously moves material across a series of rotating multiple-toothed discs. Small particles are shaken loose, larger matter is moved on.

The discs and the opening between them can be set to screen out glass, grit and ceramic material, aluminum and large fibrous matter. The high efficiencies, compact design and minimum power requirements of the disc screen are ideal for resource recovery.

Complete material examination for high efficiency

As material passes over the disc screen, it is churned and tossed by the discs. The smaller fraction is knocked loose rather than remaining trapped in fibrous material. This vigorous jogging action removes the highest possible percentage of the desired or undesired fraction.

Self cleaning for minimum downtime, high volume

The disc screen rotating discs continually clear out and move along oversize material. The interface openings remain clear and constant for accurate separation. There is rarely any need to halt material flow to clear the unit. Because the discs "carry" the large fraction by striking and bouncing it along, throughput is much higher than with other screen systems.

Discrete separation through variable openings

The disc screen can separate radically different material by selecting the proper disc profile and interface spacing. Glass, grit and ceramic; metals; and oversize fiber can be selected separately by using different configurations. Another important disc screen design feature is that discs and spacers are removable and can be changed in the field. By installing different length spacers, the action of a disc screen unit can be modified onsite.

Compact design for minimum space requirements

The disc screen is easily integrated into plant layout because of its low space requirement. And because there are no reciprocating or vibrating components, structural supportts can be simple and lightweight.

Energy efficient operation

Disc screen units have modest horsepower requirements relative to the amount of material processed. Electric or hydraulic drives may be specified to suit the application. The disc screen has been demonstrated effective on both light and heavy refuse fractions. Our engineering department can provide complete details on the correct size unit, component design and location for your application.