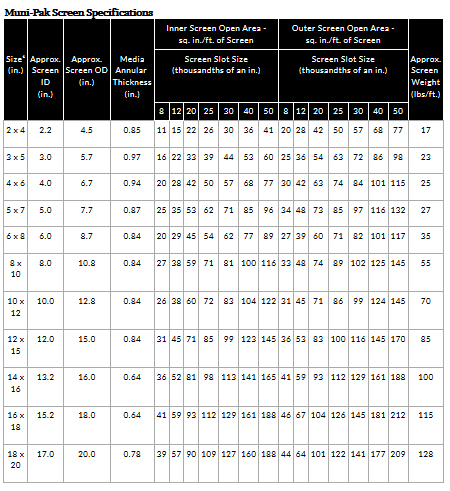

Johnson Screens - Muni-Pak Screens

Johnson Screens` solution for improving the gravel pack — the Muni-Pak screen. For contractors, this state-of-the-art, pre-packed screen eliminates the need for a larger borehole, shortens the time required to drill a well and speeds development time. It simplifies the contractor`s work and improves successful well development.

For the well owner, the Muni-Pak screen offers long-term benefits. This innovation uses ceramic or glass beads as the filter media — a concept that reduces the likelihood of filter pack fouling from biofilm and encrustation, lowering overall well maintenance costs.

Artificial filter pack is one of the most common designs used today for high-capacity municipal, industrial and agricultural wells. Before the installation of a filter pack, the contractor and the well owner must take into account some significant issues:

- The borehole must be sufficiently oversized to allow for adequate placement of the filter pack. In practice, an annular thickness of 3 to 5 in. is considered minimum. The oversized borehole is costly to the contractor (and therefore to the well owner) and keeps the crew on site for additional time.

- The filter pack must be carefully selected, placed and developed to avoid bridging and sand pumping.

- The well owner is concerned with long-term performance. Biofouling and encrustation are issues that will eventually affect performance.

Applictions

- Controls sand infiltration in new, high-capacity municipal, industrial and agricultural wells

- Can be used as a liner in existing wells to eliminate the need for constructing a new well

- Custom applications such as infiltration galleries

- Environmental remediations

- Horizontal applications

Features, Advantages and Benefits

- The pre-packed construction of Muni-Pak screens allows the use of a smaller borehole versus gravel packed filtering, with fewer cuttings, reduced circulating volume and increased uphole velocity. This feature lowers bit and cement costs and reduces the drilling time.

- Since the media is included as part of the screen package, gravel placement is not required—eliminating bridging filter packs and time spent packing, as well as reduction of equipment requirements. The results are reduced installation time and lower costs.

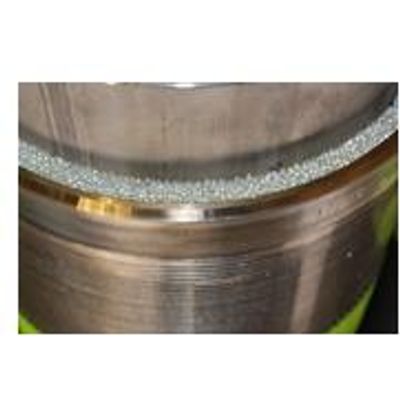

- The Muni-Pak`s dual-screen construction is four times stronger than standard rod-based screens, allowing more aggressive development and better immunity to unexpected hole problems—providing lower costs.

- A thinner filter pack results in a smaller annulus for easier development and rehabilitation of the near-well area over time, better formation penetration and more aggressive development. The benefits are a perfect media pack, reduced site time and lower risk.

- The wide range of diameters (1.25 to 20 in.) and connections (weld rings or threaded fittings) provides flexibility for meeting most application needs with a variety of standard or custom-end fittings—offering easier adaptation for a wide array of uses.

- The continuous-slot construction provides maximum open area, optimizing development and redevelopment. The result is through development.

- With custom lengths up to 40 ft., with no mid-weld, on-site welding requirements are reduced; thus, minimizing field assembly time and associated costs.

- Multiple wire-size and filter-media options enable custom applications and maximum depth capabilities, providing a wide range of uses.

- Ceramic or glass beads improves efficiency by offering excellent roundness and sphericity, a lower uniformity coefficient for better hydraulic conductivity, better flow characteristics than silica sands, less buildup of biofilm and encrustation and easier media cleaning than with irregularly shaped silica sand grains.

- Muni-Pak works great as a liner in existing well construction, eliminating the need the construction and the cost of a new.