Koch - Steam Stripping System

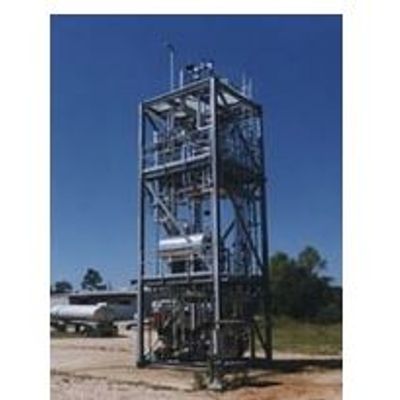

Koch Modular Process Systems, LLC. specializes in the design and construction of complete modular process systems including steam stripping of volatile organic compounds (VOC’s) from plant wastewater streams. Koch Modular provides single source responsibility, process performance guarantees, and fixed firm prices for our systems. We design and build, following the customers’ standards and specifications.

Koch Modular also provides process studies, laboratory and pilot testing, VLE development and complete process design engineering packages. For custom setups, check out the steam stripping pilot plant testing page.

Steam stripping is used to remove various organic contaminants from plant waste water in order to meet guidelines for Maximum Achievable Control Technology (MACT) standards set by the EPA. The organics and steam from the top of the column are then condensed and separated using a decanter. The condensed steam is refluxed to the top of the column.

Our modular designs provide added advantages for the steam stripping process by reducing cost and allowing for a safe installation that works around the current plant site. Also, because of the modular construction, turnaround time from purchase to implementation is reduced due to the ability to construct during permit processing and controlled fabrication sequences. Learn more about the modular process advantage.

Steam stripping, also known as steam distillation, is an economic method of cleaning up plant wastewater streams. It is a multistage continuous distillation process where steam is used as a stripping gas to remove hydrocarbons from dischargeable waste waters; all while meeting the latest EPA, PEG (Pharmaceutical Effluent Guidelines) and NESHAP regulations such as MACT, HON, and MON.

It is easy to strip VOC’s by this method if they have lower boiling points than water or have limited solubility in water. The concentrated organic product generated by the steam stripping operation is a distillate stream. It is not uncommon for this stream to be a mixture of many compounds. Furthermore, it is usually desirable to minimize the volume of this distillate because it is often sent off-site for disposal or incineration.

Typically, waste minimization is accomplished by first condensing and then decanting the overhead product from the column to separate water insoluble organics, with subsequent refluxing of the water phase from the decanter to the top of the stripping column. If the stripped organics are soluble in water, then it is typical to add several rectification stages and reflux to the stripping column to reduce the water content of the distillate. The distillate can be drawn off as a liquid product for recycle or disposal, or as a vapor product that is then fed to a thermal oxidizer.