Komax Zeta - Model 650 -Wire Processing Machine

Thanks to their five (Zeta 640) or eight (Zeta 650) process modules, Zeta 640/650 can process up to 36 wires without changeover, from batch size 1 and just-in-time. The Zeta machines assemble the required cables fully automatically on five (Zeta 640) or eight (Zeta 650) process modules from A to Z. The wire bundles are either already tied up or sorted in the correct order and prepared for further processing. This greatly simplifies and speeds up installation in the control cabinet and logistics. The data for the processing parameters can be easily converted with TopConvert via data export from any system and sent directly to the machine at the Komax interface WPCS. This means that the manual programming of articles on the machine is no longer necessary for all automated tasks already accepted. Feeding and subsequent processing are therefore error-free and highly efficient.

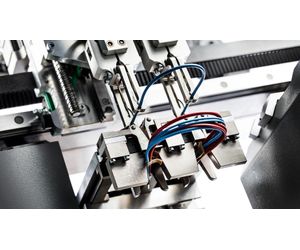

Three pairs of blades with optional incision monitoring (ACD)

The already integrated three blade pairs cover the entire cross-section range, which enables production without changeover. The ACD continuously checks the quality.

If desired, the bundler wire deposit can be tied up and sorted in the correct order, and the wires can be prepared for further processing separately according to sequences or batches.

The automatic wire changer provides up to 36 different wires from the entire cross-sectional area, thus enabling efficient processing without changeover. This covers, for instance, the wide variety of control cabinet designs.

With three shuttles working in parallel, fully automatic production is guaranteed just-in-time and from batch size 1– with consistently high quality.

To simplify processing, wires are bundled as required. Up to two inkjet printers automatically mark the wires in black and another color.