- Home

- Companies

- HiTec Zang GmbH

- Products

- LabManager System

LabManager System

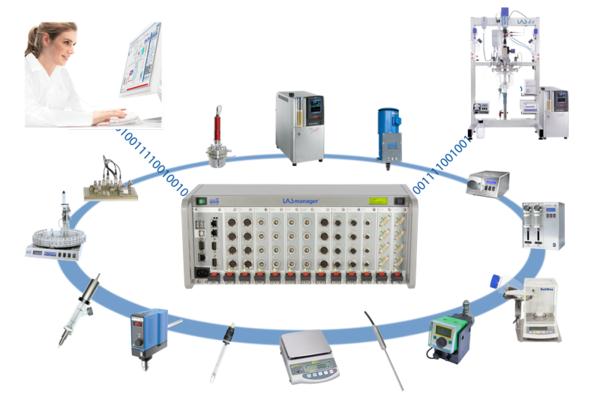

The LabManager system is on automation and/or process control system with specially suited for laboratories, pilot plant stations mini and pilot-plant equipment. It is suitable for the automation of virtually all chemical-procedures reaching from batch, semi-batch and continuous processes.The LabManager system was developed in close cooperation with specialists from laboratories and pilot plant stations s of major chemical companies.

It has proved its worth in a great number of areas as a standard tool.In accordance with the requirements of the NAMUR Working Party for research process control computersystems (RPCCS), particular care has been directed to develop a user-friendly man-machine interface, a compact design, and a high application flexibility.The LabManager® RPCCS is especially distinguished by the fact that it is also transparent and easy to handle for personnel inexperienced in automation technicians even if they want to go into details.With help from the graphically programmable recipe control system HiBatch™ and a unit operation library, acustomer without automation-technical knowledge can program the control program for a complex synthesis in a few minutes.The LabManager systems usually have a pay-back period below one year!

- More intense use of your human and capital-resources

- Glp/gmp raked working method without additional outlay

- Optimal reproducibility of your recipes, also after years

- Complete documentation of the entire process

- Savings during the instrumentation thanks to virtual devices

- Release of the lab personnel from routine activities

- Shorter "time to market" period for your products

- Increase of Quality

- Lowering of Costs

The LabManager system is on automation and/or process control system wich is specially suited for laboratories, pilot plant stations mini and pilot-plant equipment. Due to its functional variety it has been established, in research and development, as an standard for measurement and control, operation, monitoring and analysing. It has been developed consistent according to the recommendations of the NAMUR working group for Research Process Control Systems (RPCS) in cooperation with users from research laboratories of well known chemical companies.

The established Namur termination technique of LabManager and LabBox devices with standarised robust EMC-properties, extraordinary precise and robust interfaces for every standard laboratory equipment shortens setup and modification time.

This is managed by integration of all automation components like power supply for sensors and actors, programmer, transducer and power regulator. The space requirement is reduced to a minimum by the compact design of the LabManager automationsystem.

A PC with Windos operating system is used as display and operation component (ABK). Also the LabVision Software for the ABK was developed to provide the NAMUR recommendations for Research Process Control Systems and stands out on top from other PCS-Software.

Online configurability allows changes during operation without shutting down the running process. Realisation of the NAMUR basis operation concept for the recipe method guarantees the necessary flexibility for frequently changing tasks in laboratories.

The self-explanatory multitasking plain text control language HiText, which renounces cryptic elements, can be learned in a short time also by users without programming experience.

HiTec Zang provides always available after sales support. Like an hotline with qualified experts, flexible trainings or remote maintenance via Internet, TDSL, ISDN or analogue modem. With a minimum of effort we can support you always. All of this gives you the assurance that you have decided for the right automation system in all respects.

In laboratory automation single components have been like dosing controllers, pH or vaccuum controllers, data logging and control systems have been state of the art. The flexibility, the scope of services and the use of a LabManager system however reach far beyond this basic configuration of laboratory automation. The LabManager system is suitable for automation purposes of continuous and batch process in chemistry, pharma, biotechnologie and food. all available automation functions are introduced in a single, compact device with nearly infinite possibilities. External transducers, controlled loops, control devices, power supply etc. are no longer necessary. Therefore the common control cabinet and the attached costs of producing and maintenace are turned over. Resourcful space in a laboratory is being saved.

- One and Multi Vessel Plants

- Semi Batch Processes

- Micro Reaction Technology

- Process Development

- Process Optimization

- Screening

- Scale-Up

- Quality Assurance

- Production Oriented Labs (Verification)

- Syntheses

- Polymerization

- Destillation

- Rectification

- Extraction

- Hydrogenation

- Crystallization

- Fermentation

- Reaction Calorimetry, etc.

- Measuring

- Process monitoring

- Alarming

- Logging

- Process Control

- Recipe Control System

- Automatic Control

- Process Visualization

- Filing

- Analysis

- Documentation

- Presentation

The laboratory automation systems are modularely engineered and can be equipped for and purpose. The spectrum reaches from a simple measuring data logger to a networking process control system with thousands of inputs and outputs. Bigger laboratory automation systems are being realised by linking multiple devices.