- Home

- Companies

- LanzaTech Inc

- Products

- LanzaTech - Carbon Recycling Technology

LanzaTech - Carbon Recycling Technology

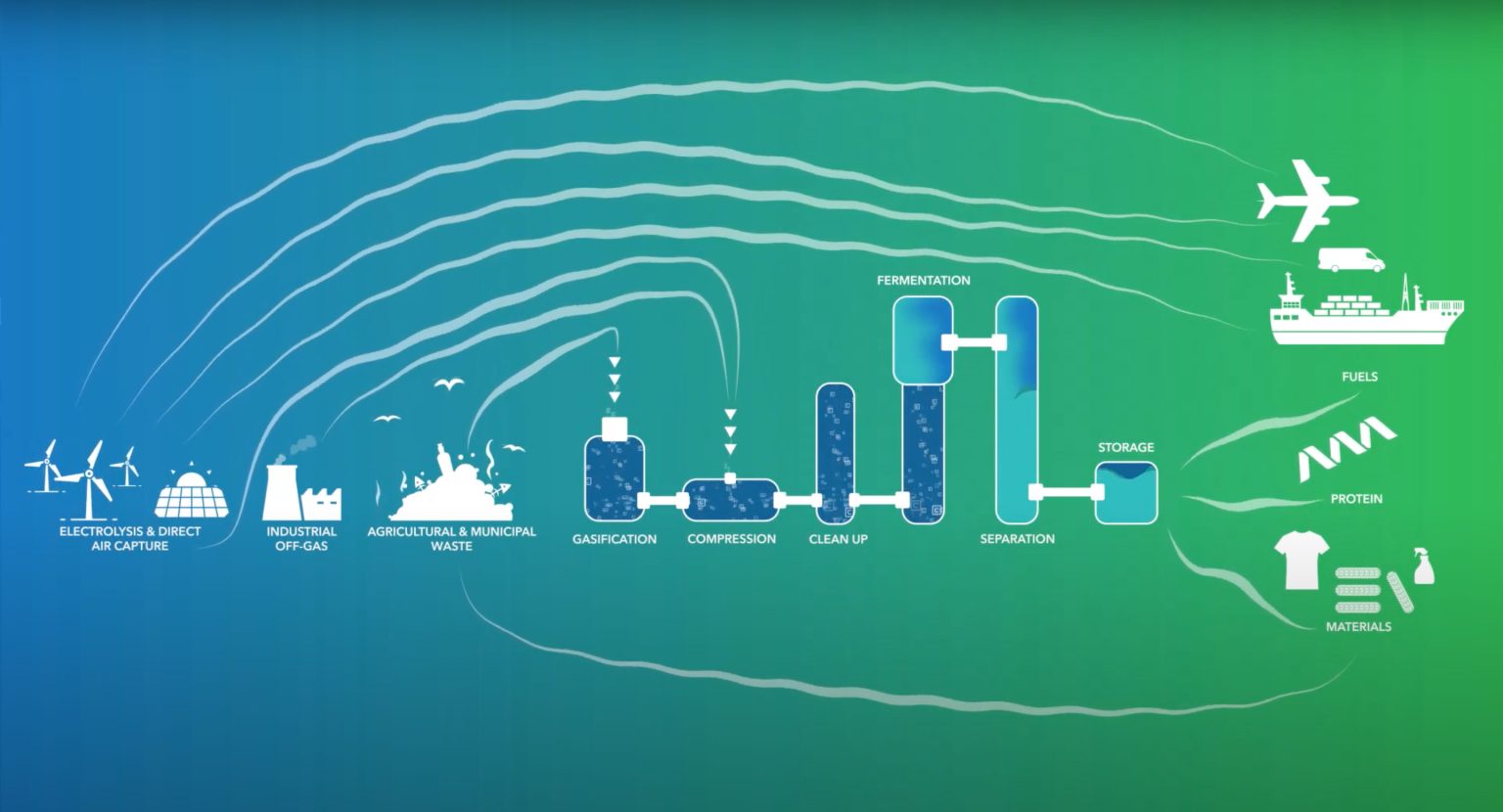

Our way of life is built on carbon, from our fuel sources to the materials in our consumer products, but we need a more sustainable way to source it to protect the future of our planet. LanzaTech takes carbon capture a step further by transforming it into something valuable and useful at scale that directly replaces virgin fossil carbon in consumer goods and sustainable aviation fuel alike.

With our technology licensing model, we enable industrial partners to capture and process carbon-rich gases before they enter the atmosphere and cause environmental harm. We`ve been operating at commercial scale since 2018 and have proven that our biorecycling approach is playing a pivotal role in keeping our planet livable for the long term.

Decades ago, we recognized the harm humans were causing our planet. So, we implemented recycling programs, bought organic foods, and joined the fair-trade movement. Today, companies offer products made from recycled plastic, lab grown protein, and governments are creating legislative landscapes to support a Net Zero future.

LanzaTech’s carbon recycling technology is like retrofitting a brewery onto an emission source like a steel mill or a landfill site, but instead of using sugars and yeast to make beer, pollution is converted by bacteria to fuels and chemicals. Imagine a day when your plane is powered by recycled GHG emissions, when your shampoo bottle started life as emissions from a steel mill. This future is possible today using LanzaTech technology and LanzaTech’s CarbonSmartTM IP licensing services.

Life cycle analysis (LCA) is essential for understanding the environmental benefits of LanzaTech’s technology. LanzaTech has developed in-house LCA expertise and engages in collaborations to understand and develop recommendations for methodological approaches which vary by region. We regularly work with specialists around the world including: The European Commission (EC)/ Joint Research Council (JRC), Roundtable for Sustainable Biomaterials (RSB), International Civil Aviation Organization (ICAO), International Sustainability & Carbon Certification (ISCC), California Air Resources Board (CARB), Argonne National Laboratory (ANL), Michigan Technological University (MTU), Massachusetts Institute of Technology (MIT) and others.

LCAs consider the impacts of producing and using all energy and chemical inputs into the final product(s). Third party analyses are used wherever possible and are available to our customers. We also conduct LCAs for peer review, using in-house engineering data and emission factors from appropriate published LCA-specific databases and third-party market projections.

Here you can find an example of a peer reviewed LCA for carbon negative chemicals production, published in Nature Biotechnology.

Here is an example of a third party LCA for high purity ethanol which includes transportation to Europe. As more facilities using our technology come online globally, the impact of transportation on the LCA will be greatly reduced. LanzaTech continues to conduct LCAs on each facility, exploring different methodologies and parameters. We are currently completing an internal review of an LCA of the same facility for fuel grade ethanol to the factory gate. This will be published after it has been reviewed by a third party. Current estimates of the resulting LCA show a significant reduction relative to high purity ethanol being shipped to Europe.