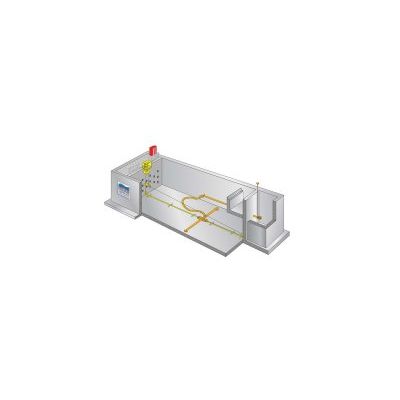

Leopold - Model CT2 -Submerged Sludge Collector

By simplifying the water treatment process, Xylem’s Leopold CT2 sludge collection system increases plant efficiency, and reduces both maintenance time and total system operational costs. Xylem`s Leopold CT2 submerged sludge collector systems have quietly done their job, delivering reliable operation, low maintenance costs, and good sludge production in hundreds of facilities worldwide.

The CT2 sludge collection system operates on gravity, both a simple principle and powerful force. Xylem designed a superbly simple but highly efficient process to remove sludge by taking advantage of a differential head. Water pressure in the main tank forces the sludge through the collection header into the outlet piping, and away to the sludge removal trough. Careful selection of smooth-bore piping for the suction header keeps headloss to a minimum for the most efficient sludge removal and low driving head requirements. A simple cable drive moves the suction header across the tank floor at a steady, controlled rate, removing sludge without disturbance. Pumping costs are eliminated and cable drives require far less power.

The Leopold CT2 submerged sludge collection system has a “fit and forget” quality that not only simplifies the water treatment process, but also reduces system operation costs. The header, locked onto the guide rail and controlled by a programmable operating system, targets the areas of highest sludge accumulation. The cable drive pulls the header through the sludge with a positive motion and minimal sludge disturbance, removing the sludge without dilution. This reduces sludge volumes and thickening costs, too. And compared to other submerged sludge collectors, the Leopold CT2 submerged sludge collection system is far simpler to maintain because it has a minimal number of moving parts.

Adaptable to plant requirements

The Leopold CT2 sludge collection system can be easily installed or retrofitted into a plate settler or tube settler sedimentation tank. Good quality sludge can then be removed as raw water conditions demand.

The CT2 sludge collection system is the optimum choice for flat-bottom tanks or tanks with sloped floors. As the suction header glides through the sludge, it removes the settled sludge with minimal dilution and without gross disturbance.

Leopold controls for the CT2 sludge collection system can give each plant the flexibility to meet its individual needs. For example, in sedimentation basins sludge settles unevenly, with more accumulating in the inlet area than in other areas of the basin. Advanced Leopold controls can be programmed to increase sludge removal at the inlet of the tank to even out the sludge load, providing consistent sludge for thickening and disposal.

The CT2 sludge collection system can also be designed to compensate for high-solids-production water with a double header driven by a single cable system. The travel length of the header is designed to draw the desired amount of sludge from the basin where sludge production is greatest. Double headers also accommodate extra-long basin design.

The Leopold CT2 sludge collection system can be designed to accommodate extra-wide sedimentation tanks as well. And each track can be separately controlled to vary the number of passes and the speed of each pass.

- High solids concentration

- Targets the areas of highest sludge accumulation

- Trouble-free maintenance

- Reduced operational cost

- Operates via differential head, with no pumps to maintain

- Energy efficient

- Adaptable to a wide range of tank configurations

Technical Information

General Information

- Basin size Can accommodate extra-wide sedimentation tanks by being placed in parallel, up to 120` long

- Construction type New or existing

- Contaminates removed Suspended Solids, Algae, BOD/Organics, Ortho-phosphorus

- Misapplications Heavy Silts and Sands

- Removal principal Differential Head

- Removal speed Up to 12 fpm (4 M/min)

- Single source responsibility Yes, to supply all system components

- Sludge removal applications Potable Water Clarification (Traditional Sedimentation / Plate / Tubes), Filter Backwash Water

- Smart control Multi-Pass Control Option to target sludge profile

- Standards met AWWA, ASTM, ASME

System Components

- Control system Manual, Semi-Automatic, Automatic

- Drive system Low horsepower, high efficiency variable speed drive assembly with fiberglass cover

- Guide rail 304 or 316 stainless steel construction

- Header swivel PVC Swivel Assembly to Extend Hose Life

- Suction header 304 or 316 stainless steel locked to guide track via rollers to prevent derailment

- Suction hose Neutrally Buoyant, Long-Life Polymer Construction

- System control Manual, PLC, SCADA Integrated

- Valve actuator Electric, Pneumatic

- Valves Butterfly

Technical Features

- System control

- Manual, PLC, SCADA Integrated

Xylem offers a range of advanced wastewater and water solutions to help operators around the world achieve their required water effluent while delivering optimal performance, reliable operations and substantial energy savings no matter what industry or application. Working with customers, Xylem listens, learns, and adapts to local environments, ensuring the best possible design, customized to meet their specific needs. Below are some recommended industries and applications.