Leopold - a Xylem Brand products

Food & Beverage

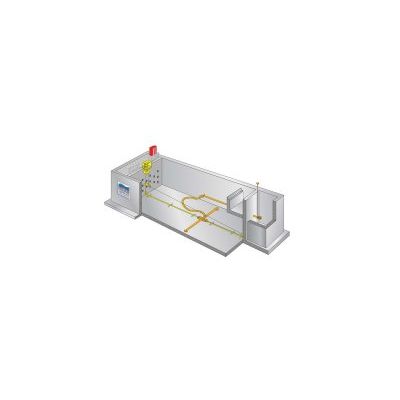

Leopold - Submerged Sludge Collector

By simplifying the water treatment process, Xylem’s Leopold CT2 sludge collection system increases plant efficiency, and reduces both maintenance time and total system operational costs. Xylem`s Leopold CT2 submerged sludge collector systems have quietly done their job, delivering reliable operation, low maintenance costs, and good sludge production in hundreds of facilities worldwide.

General Industry - Membrane Filtration

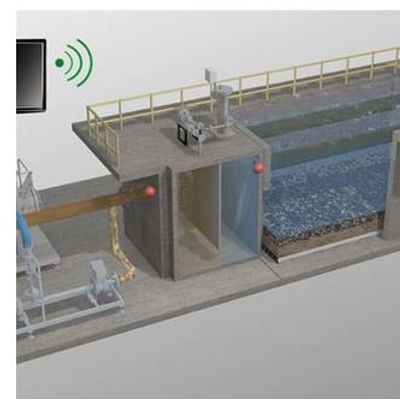

Leopold - Floating Sludge Collector

Xylem’s Leopold Clari-Vac floating sludge collector removes material faster – up to 12 fpm, produces a higher solids content, lowers sludge disposal costs, drastically reduces power costs, and virtually eliminates maintenance. Clari-Vac sludge collector has proven to be energy efficient. In fact, it uses up to 80% less power than other system. The simple, but rigid construction of the Clari-Vac floating sludge collector allows for trouble-free maintenance during tank drain-down. There are no moving parts under water and all parts except the drive are nonferrous metals to minimize corrosion potential.

Leopold - Filterworx Performance Filter

Leopold engineers have been at the forefront of gravity media filtration since 1924. With more experience than anyone in the industry, we can help you analyze, evaluate and design all aspects of your complete filtration system.

General Industry - Raw Water Intake and Process Water Supply

Leopold - Backwash Water Troughs

Xylem`s Leopold fiberglass backwash water troughs are used in water and wastewater filters to provide uniform removal of wash water during backwashing. A wide selection of carrying capacities will meet any design requirement. Molded of densely laminated fiberglass-reinforced plastic, Xylem`s troughs are durable, corrosion resistant, reinforced for strength and stiffness, and maintenance free. They are easy and economical to install, with no costly forming work, and all mounting brackets, hardwre, and stabilizers are stainless steel. The optional stainless steel Trough-Guard media retention baffles reduce media loss during a sustained air/water backwash over the wash-water trough weir edge.

Leopold - Engineered Filter Media

Whether mono-media deep bed, dual media, or tri-media, Xylem carefully evaluates influent water characteristics and process requirements. Next the right configuration of media, with the effective size and uniformity coefficient to give energy efficient, consistent and long term performance is provided. Leopold Engineered Filter Media products are processed in a unique, stat-of-the-art facility specifically designed to produce anthracite filter media with low uniformity coefficients (UC). What truly sets Xylem apart from most of other media processors is moisture reduction prior to screening. Reducing the moisture in the raw feedstock greatly enhances screening efficiencies, enabling more anthracite to be shipped – and less water – and to produce multiple distinct media sizes all with UCs below 1.30.

Leopold - Media Retainer

Providing a more effective option than using gravel in most applications, the I.M.S® 1000 media retainer is engineered to allow for improved backwashing and improved air and water distribution for cleaner media. Thanks to its physically rigid construction and precision engineered injection molded slots, the I.M.S 1000 media retainer eliminates dead spaces and provides longer filter runs reducing overall operating costs. The patent pending baffles on the bottom of the plate are designed to ensure air doesn’t roll to the high end of the cap.poridium.

Leopold - Underdrain System

Underdrains collect filtered water during the filter run, and distribute air and water during the backwash cycle. Providing cleaner filters mean longer filter runs and higher water efficiency, more product water, and less waste. This lowers your operating costs per gallon or liter of filtered water. All Leopold underdrains deliver the superior performance that has made the Leopold underdrain the industry leader.

Life Sciences, Pharma & Biopharma

Leopold - Oxelia System for Reuse or Sensitive Waters

Destroy tough contaminants and pathogens with powerful oxidation enhanced biofiltration. Using strong oxidation to break the bonds of recalcitrant organics, Oxelia destroys their dangerous chemical properties and converts them into biodegradable organics. Naturally occurring microorganisms in the biologically active carbon filter consume these partially oxidized organics, totally removing them from the wastewater stream.

Municipal Drinking Water Treatment and Distribution

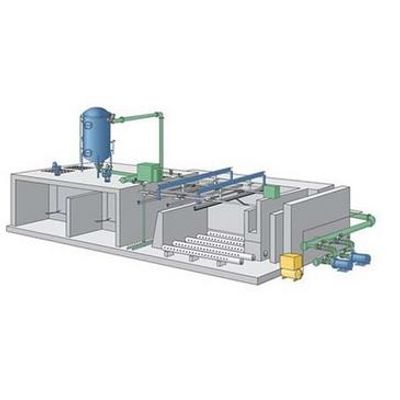

Clari - Dissolved Air Flotation System (DAF)

Xylem’s Leopold Clari-DAF system is a clarification technology for the pretreatment of rapid gravity and membrane filter feed water. It’s a highly-effective, proven technology for removing low-density particulates found in lakes and reservoirs, which are problematic for typical sedimentation systems. The Clari-DAF system excels at removing filter clogging algae and precipitated solids (TOC, Fe, Mn), as well as Giardia and Cryptosporidium. It is also an unsurpassed system for treating open seawater intakes with contaminants such as algae (red tide) and free or emulsified oil that are naturally buoyant and best removed by flotation.

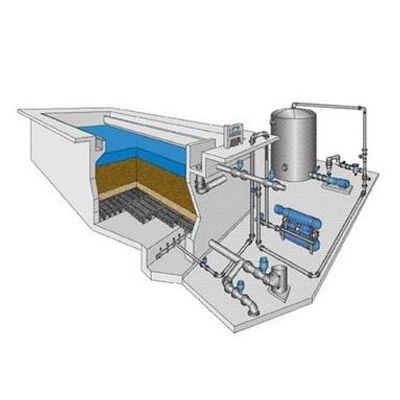

elimi-NITE - Denitrification System

Leopold elimi-NITE 2.0 denitrification system is an effective method of reducing nitrate nitrogen in the effluent stream of a wastewater treatment plant by converting nitrate nitrogen to nitrogen gas. The biological conversion is done in an attached growth, downflow, deep bed, mono-media filter. Dissolved oxygen is removed to create an anoxic environment for denitrification, and particulate matter is removed so insoluble phosphorous is removed, as well. The system adds supplemental carbon source or microbiological food needed to metabolize the nitrogen.