LEVAPOR GmbH, Biofilm Technologies

- Home

- Companies

- LEVAPOR GmbH, Biofilm Technologies

- Products

- LEVAPOR-C Adsorbing, Porous Carrier ...

LEVAPOR-C Adsorbing, Porous Carrier Material for Special Microorganisms

LEVAPOR-C is an innovative carrier material for the immobilization of microorganisms, consisting of a porous polymeric matrix with a specially activated surface.

Most popular related searches

sludge processing

contaminated groundwater

effluent treatment

sludge removal

trickling filter

activated sludge

waste contaminated soil

sludge bed reactor

flocculant

flocculator

The biotreatment of complex effluents, containing poorly degradable pollutants is often problematic, because it requires special strains, which show poor sedimentation, leading to their wash-out from the reactor and resulting in a less efficient biotreatment process.

A very effective method to improve bioprocesses is the immobilization of the biomass, which means the fixation of microbial cells on solid surfaces by building biofilms resulting in higher

- biomass concentration in the bioreactor,

- degradation efficiency and process stability,

- resistance to temperature-, pHand toxic/load peaks and

- a lower yield of excess sludge production.

LEVAPOR-C should be used, if

- the effluents show

- slow growth,

- qualitative fluctuations,

- high salinity and/or

- toxic or inhibitory effects.

- the biomass shows

- low biodegradability

- low tendency to flocculation and/or * low settling velocity.

The activation of the surface results in

- faster wetting and

- better colonization of the LEVAPOR-surface with microorganisms and in adsorptive

- binding of pollutants

Biological treatment of

- municipal and indstrial waste water

- contaminated groundwater and soils and

- waste gases with immobilized specialized microorganisms

LEVAPOR can be applied in following effluent treatment processes and situations:

- nitrification

- poorly degradable pollutants

- inhibitory pollutants

- suboptimal flocculation and settling behavior

- high salinity effluents

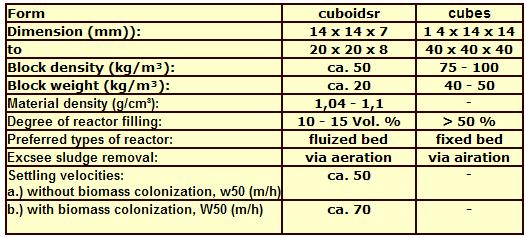

Types of bioreactors

- Activated sludge process:

- fluidized bed reactors,

- 12 to 15 vol.% degree of filling,

- retention of LEVAPOR-C in the reactor

Bio-Trickling Filters

- for waste water and waste gases

- 50 to 75 vol.% degree of filling

The activated surface results in faster and better

- wetting and fluidization of the carrier material,

- binding of toxic pollutantsvia adsorption,

- colonization with microorganisms

- The increased quantity of biomass in the reactor achieve

- higher process stability,

- higher volume-time-yields and

- higher sludge age.

- Protection of organisms inside of the carrier, against high shear forces and inhibitors

- Retention of slowly settling biomass

- Low degree of reactor filling

- Existing basins can be upgraded

- Very good colonization of the inner surface

- Optimal mass transfer into the carrier/microbial cell

- Simple retention of the carrier

- Special efforts for excess sludge removal not required