- Home

- Companies

- Integrity Municipal Systems (IMS)

- Products

- IMS - Model A-758 - Lime Slaking System

IMS - Model A-758 -Lime Slaking System

Lime is one of the most common and economical chemicals used in the water and wastewater treatment process. The cost of commercial bulk hydrated lime or prepared lime slurry solutions, however, becomes prohibitive for installations requiring a continuous, high volume supply, typically greater than 45 kgs/hr (100 lbs/hr). To help alleviate this cost, on-site slaking or hydration is the ideal solution. The Series A-758 lime slaker provides for reliable, efficient slaking of various grades of quicklime (CaO) at a substantial savings over other slaking methods. Through the pioneering use of paste-type slaking technology, the Series A-758 lime slaker consistently produces a more reactive lime slurry requiring less energy and less operator attention. The compact size and flexible configuration make this pre-engineered system ideal for new and retrofit installations.

- Saves water, heat and power

- ƒEconomical and reliable on-site slaking

- ƒEasy to install, unit is factory pre-tested

- ƒChoice of final slurry concentration

- ƒFlexible controls: manual, flow proportional, and automatic start-stop

Superior Paste-Slaking Process

Utilizing a 2:1 water-to-lime ratio, the A-758 unit slakes lime as paste which provides a number of benefits over the more traditional 4:1 water-to-lime or slurry slaking process. This includes less power, faster slaking, a smaller footprint and, most importantly, a more reactive lime slurry solution.

Saves Power

The 2:1 paste slaking process generates its own slaking heat from the hydration heat of reaction (CaO+H20 = Ca(OH)2 + Heat (490 btu/lb)). This avoids the need and expense of an external heat source, internal heat exchangers, and temperature control systems. Additionally, slow speed agitation requires one-half the horsepower of equivalent sized slurry slakers.

Fast Slaking

The low water-to-lime ratio and high self-generating heat of reaction completes the slaking process in approximately five minutes. This short retention time leads to efficient start-stop or batching operation and rapid changes in lime concentration when required.

Compact Size

The 2:1 slaking ratio and short retention time allows for a smaller slaking compartment without bulky insulation or any need for a water jacket. The A-758 lime slaker takes about 20% less floor space than other designs.

More Reactive Hydrate Particles

The intense heat [>82° C(180° F)] generated by the 2:1 slaking ratio subjects the quicklime to steam penetration. The resulting internal pressure promotes the fracturing of the quicklime into smaller, highly reactive particles. This means more surface area for more efficient lime usage.

Controlled Consistency

An automatic, torque-actuated water inlet valve provides precise, continuous control of paste consistency and, therefore, the slaking process. Variations in lime quality and feed rate are quickly recognized and the optimum slaking rate is maintained, without operator intervention.

Integrated System Design

The pre-engineered A-758 lime slaker system is available with a broad range of capacities, capabilities and control options:

- ƒFour different capacities from 450 to 3600 kgs/hr (1000 to 8000 lbs/hr)

- ƒSpecific gravity classification or screen-type grit removal technology

- ƒGravimetric or volumetric belt-type lime feeders or screw-type lime feeder

- ƒPLC or relay logic controls with an optional automatic batching function

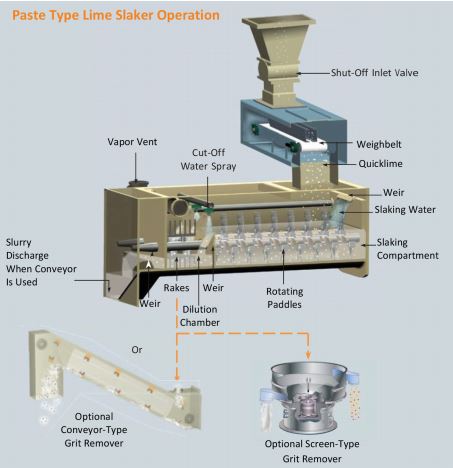

Water and quicklime (CaO} are fed into the slaker mixing compartment at an approximate 2:1 ratio. The lime is metered by either a gravimetric weighbelt feeder or a volumetric screw or belt-type feeder. Controlling the lime feedrate determines the output of the slaker system. The water flow is automatically controlled by a torque-sensitive water adjusting valve.

In the slaking compartment, two intermeshing paddle shafts, rotating in counter-clockwise directions, mix the quicklime and water into a paste-type composition, controlled by the torque valve to the 2:1 slaking ratio. Any variation in the paste consistency caused by vapor loss, lime quality or size fluctuations, or changes in the lime feed rate, results in a different torque load on the paddle shafts. This causes the torque valve to adjust the water flow to maintain the desired paste consistency.

The paste and entrained inert grit moves forward in a plug-flow fashion. After approximately 5 minutes, the completely slaked lime paste flows over a weir into the dilution compartment. Here water nozzles direct a cut-off spray to dilute the paste into a lime slurry at an approximate 4:1 concentration. This also releases the grit from the lime paste so that it can be removed. Two sets of rotating rakes keep the lime in suspension and help move the grit to the grit separator.

Dust and steam, generated by the exothermic reaction of the lime and water, are drawn off by an integral, water operated vapor-dust arrestor. The steam and dust are condensed and returned to the dilution compartment. Excess steam and water vapor are vented outside of the slaker.

A low water pressure switch in the torque valve piping is designed to stop the lime feeder when the supply pressure falls below the minimum operating requirement. This avoids heat build-up due to insufficient slaking water. The feeder automatically restarts when the pressure is restored.

- Capacities : 450,900,1800, and 3600 kg of quicklime per hour (1000,2000, 4000, and 8000 lbs/hr).

- Operating Range Up to 20:1

- Slaking Ratio : Approximately 2:1 water to lime by weight before dilution.

- Lime Feeder : Three types of feeders available: Series 31-165 Gravimetric weighbelt feeder; Series 32-215 Volumetric belt-type feeder and/of Series 32-300 screw-type feeder.

- Control Panel : For local or remote mounting. NEMA12; 230/460 VAC, 3 ph, standard; 115 VAC, 1 ph, optional (not available with 3600 kg/hr (8000 Ib/hr) capacity).

- Paddle Shaft Mixer Motors

- 452 kgs/hr (1000 lbs/hr) capacity -1/2 hp;

- 900 kgs/hr (2000 lbs/hr) capacity -1 hp;

- 1800 kgs/hr (4000 lbs/hr) capacity -1-1/2 hp;

- 3600 kgs/hr (8000 lbs/hr) capacity - 2 hp;

- Standard is 230/460 VAC, 60 hz, 3 ph.

- Single phase motors are available up to 1800 kgs/hr (4000 lbs/hr).

- Conveyor-Type Grit Remover Motors : 1/4 hp, 230/460 VAC, 60 hz. 3 ph, totally enclosed. Also available in single phase up to 1800 kgs/hr (4000 lbs/hr) capacity units.

- Screen-Type Grit Remover

- 450 kgs/hr (1000 lbs) slaker -1/3 hp;

- 900 and 1800 kgs/hr (2000 lbs & 4000 Ibs/hr) slakers -1/2 hp;

- 3600 kgs/hr (8000 lbs) slaker - 2-1/2 hp;

- All motors are 230/460 VAC, 60 hz, 3 ph. 1200 RPM TENV.

- Booster Pump Motors (High Slurry Concentration Option)

- 450 and 900 kgs/hr (1000 and 2000 lbs) slakers -1/2 hp;

- 1800 kgs/hr (4000 lbs) slakers -11/2 hp;

- 3600 kgs/hr (8000 lbs) slaker - 2 hp;

- All motors are 230/460 VAC, 50/60 hz, 3 ph, TE turbine, all bronze housing. Note: Only available with screen-type grit remover.

- Water Requirements : Recommended supply pressure for 450 to 1800 kgs/hr (1000, to 4000 lbs/ hr) slakers, 2.7 bar (40 psi) minimum and 5.2 bar (75 psi) maximum; for the 3600 kgs/hr (8000 Ibs/hr) slaker, 3.8 bar (55 psi) minimum and 5.2 bar (75 psi) maximum.

- Control options

- Manual speed control of feeder via a potentiometer on the control panel.

- Automatic speed control of the lime feeder via a 4-20 mA input signal.

- Automatic batching and automatic system shut-down via optional start-stop configuration.

- Dimensions : Complete dimension details can be found in catalog numbers WT.330.100.100.UA.CN to WT.330.100.126.UA.CN.