- Home

- Companies

- Lindner-Recyclingtech GmbH

- Products

- Lindner Antares - Model 1300/1600/1900 ...

Lindner Antares - Model 1300/1600/1900 -Stationary Universal Shredding Machine

NEVER LOSES OUT: EFFICIENT TECHNOLOGY IN A COMPACT PACKAGE. With its robust design, easy maintenance access and enormous power, the Antares series combines all the advantages of a Lindner shredder in one compact machine. The wide range of sizes allows you to adapt the shredder to your specific downstream requirements. Enjoy seamless processing with consistent particle size. More info on: www.lindner.comLindner`s original: tried and tested a thousand times over, our internal pusher allows for easy and secure machine feeding. Our years of experience and continuous development have left their mark on its distinctive design.

Continuous shredding

due to smooth feeding.

Easy Feeding

with a completely internal construction. Maintenance-free thanks to the absence of guide elements.

No jamming

as a result of additional comb and sealing bars.

The swivel-mounted, hydraulically operated screen unit allows for easy and comfortable access for maintenance and refitting. The screens are available with various mesh widths and can easily be changed by hand by just one person – so you can quickly customise the shredder to the particle size you need.

Easy Access for Maintenance and Fitting

thanks to the swivel-mounted, hydraulically operated design.

Flexible Output Sizes

made possible with our screen units in various hole sizes.

Extremely Safe Operation

with the electromagnetically locked screen access point, preventing access to the cutting chamber while the machine is in operation.

The Antares’ individually configurable square cutting system ensures maximum output while taking up minimum floor space. The cutting system is designed with various applications in mind, ensuring efficient shredding of a wide range of materials. As usual, the cutting system is mounted on the quick-change mechanism that is typical of Lindner products to make maintenance quick and easy.

Optimised Output

thanks to the customisable cutter configurations.

Consistent Particle Size

fully adjustable cutting gap.

Low Wear and Tear

ensured by optional cutting system and cutter holder hardfacing.

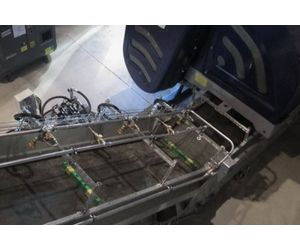

Our optional water sprinkling system to reduce air-borne dust at the filling area offers a central water pipe with four nozzles in the enclosed hopper with suction point which can be easily activated via the control panel or the remote control. The system is designed for year-round use (down to -25°C).

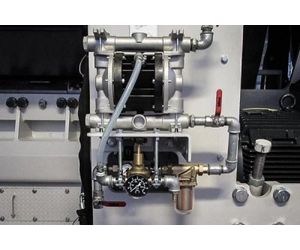

Fire Extinguishing System With Spark Detection

The fire extinguishing system detects sparks and overheated objects, protecting the system when easily flammable materials are being processed. The sensors monitor not only the shredder but also the discharge conveyor and where necessary trigger the extinguishing process. Thanks to the central water supply, the pressure tank is subsequently filled automatically and once again ready for use.