- Home

- Companies

- Lindner-Recyclingtech GmbH

- Products

- Lindner Komet - Model 2200 HP /2800 HP ...

Lindner Komet - Model 2200 HP /2800 HP -Stationary Secondary Shredder

GIVES YOUR PROCESS A BOOST: MORE KNIVES,MORE EFFICIENCY. The Lindner Komet HP is synonymous with high performance in secondary shredding. With an output 60% higher than the standard Komet series and two additional knife rows, the shredder guarantees enormous production capacities. High-precision electronics in combination with particularly robust housing components ensure the machine’s enormous durability, even under the toughest conditions. And it produces consistently high-quality SRF – which is what the name Komet stands for. More info on: www.lindner.comLindner`s original: tried and tested a thousand times over, our internal pusher allows for easy and secure machine feeding. Our years of experience and continuous development have left their mark on its distinctive design.

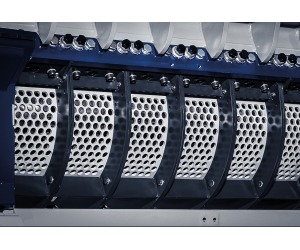

Get up to 60 % more throughput compared to our standard Komet with this shear cutting system designed for maximum output that sports seven rows of cutters, and enjoy consistant particle sizes with our proven cutting principle and cutting gap that is even adjustable in operation.

Seven rows of knives

for over 5,000 cuts per minute.

Parts storage made easy

thanks to identical knives, counter knives and scrapers. Consistent particle size with a cutting gap fully adjustable even during operation.

Maximum service life

ensured by quadruple-use, quick-change knives.

Tried and tested a thousand times over, this Lindner gearless belt drive ensures efficient and reliable power transmission. With simple and maintenance-free construction as well as readily available spare parts worldwide, this machine guarantees the highest possible uptimes.

with high-performance ABB motors.

Efficient, stable and gearless

belt drive.High-precision electronics for precise drive control.

of easily exchangeable standard parts.

The torque-limiting clutch protects against damage to the drive unit when blockages are caused by foreign objects. Furthermore, the highly precise sensors facilitate the controlled powering down of the machine to preserve all components.

Complete Drive Protection

thanks to the drive unit’s instant mechanical disengagement.

Secure Power Down

with our proven sensors.

Fully Adjustable

to various materials.

The swivel-mounted, hydraulically operated screen unit allows for easy and comfortable access for maintenance and refitting. The screens are available with various mesh widths and can easily be changed by hand by just one person – so you can quickly customise the shredder to the particle size you need.

Flexible Output Sizes

Made possible with screen units in various hole sizes.

Extremely Safe Operation

With the electromagnetically locked screen access point, preventing access to the cutting chamber while the machine is in operation.

Easy Access for Maintenance and Fitting

Thanks to the swivel-mounted, hydraulically operated design.

The hydraulically operated, inward-opening maintenance door allows you to quickly and safely access the cutting system for maintenance work or swiftly remove foreign objects with minimum material leaks.

Remove Non-Shreddables Quickly and Cleanly

with the maintenance door at position 2.

Enjoy Convenient Maintenance Access

to the cutting chamber with the maintenance door at position 3.

100% Safe Operation

due to the mechanical safety lock and the pusher`s special parking position.

Legal directives in Europe, North America and Asia regulate the intended use of equipment in environments with explosive atmospheres, with zone classifications determining the minimum requirements for machines, components and inert materials. In accordance with the EU ATEX (Atmosphères Explosibles) directive for shredders, Lindner offers you products for use in zones 21 (shredders – indoors) and 22 (shredders – outdoors).

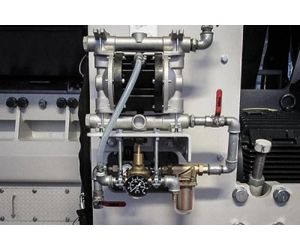

Our optional water sprinkling system to reduce air-borne dust at the filling area offers a central water pipe with four nozzles in the enclosed hopper with suction point which can be easily activated via the control panel or the remote control. The system is designed for year-round use (down to -25°C).

Fire Extinguishing System With Spark Detection

The fire extinguishing system detects sparks and overheated objects, protecting the system when easily flammable materials are being processed. The sensors monitor not only the shredder but also the discharge conveyor and where necessary trigger the extinguishing process. Thanks to the central water supply, the pressure tank is subsequently filled automatically and once again ready for use.

Rotor Cooling System

The closed-circuit rotor cooling system allows for unproblematic shredding of temperature-sensitive materials with low melting points and prevents the final product from lumping as a result of the heat created during the shredding process.