- Home

- Companies

- Lindner-Recyclingtech GmbH

- Products

- Lindner Polaris - Model 1800 / 2200 / ...

Lindner Polaris - Model 1800 / 2200 / 2800 -Stationary One-Step Shredder

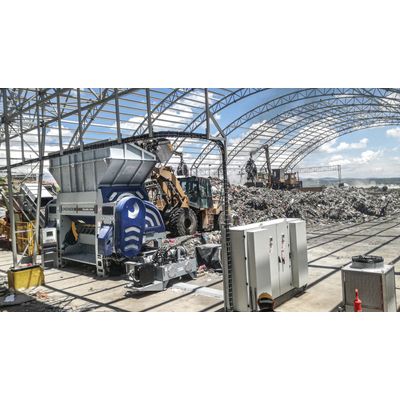

MAKES SHORT WORK OF SHREDDING: COST-EFFICIENT, HIGHLY RELIABLE AND ONE STEP. Nothing can withstand the enormous power of the Lindner Polaris single-shaft shredder. Made for one-step processing of untreated municipal, industrial and commercial waste to obtain mid-calorific fuels (40 - 120 mm) ideal for co-incineration in calciners at cement works. Sturdy design and low operating costs are the hallmarks of this highly specialised shredder: enjoy uninterrupted shredding excellence 24 hours a day, seven days a week. With maximum efficiency throughout, as demonstrated by a field test: thanks to the countershaft drive, the Lindner Polaris shreds twice as much material as comparable machines in the same period of time. More info on: www.lindner.com

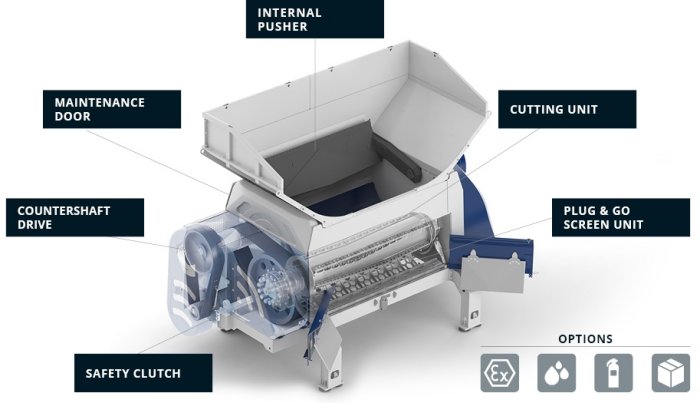

Internal Pusher

Lindner`s original: tried and tested a thousand times over, our internal pusher allows for easy and secure machine feeding. Our years of experience and continuous development have left their mark on its distinctive design.

Consistent dosing enabled due to self-regulating hydraulics.

No jamming

as a result of additional comb and sealing bars. Maintenance-free thanks to the absence of guide elements.

Easy feeding

with a completely internal construction.

More efficiency with our smart technology: our countershaft drive stores and releases rotational energy depending on the load, meaning more power yet less energy consumption.

Load-Dependent Energy Release

thanks to countershaft drive.

Readily Available

Our easily replaceable standard components are readily available worldwide.

More Power for Tough Materials

ensured with additional flywheel mass.

Readily Available Worldwide

due to easily exchangeable standard parts.

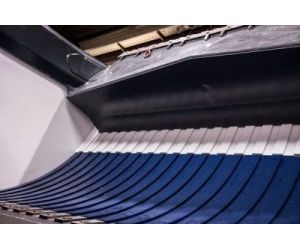

The swivel-mounted hydraulically operated screen unit allows for easy and comfortable access for maintenance and refitting. The screens are available with various mesh widths and can easily be changed by hand by just one person – so you can quickly customise the shredder to the particle size you need.

due to our swivelmounted, hydraulically operated screen unit with individual screen modules.

Flexible output sizes

made possible with quick-change screen units in various hole sizes.

Extremely safe operation

thanks to the electromagnetically locked screen access point, preventing access to the cutting system while the machine is in operation.

The shear cutting system specially developed for untreated municipal, commercial and industrial waste can handle even the most difficult materials. The secret to its productivity are the extremely hard steel alloys and the robust cutters and cutter holders designed to withstand even the hardest foreign objects.

guaranteed with signature knife geometry.

Parts storage made easy

with identical knives, counter knives and scrapers. Resistant to foreign objects owing to sturdy knives in welded knife holders.

Long service life

as a result of multiple- use, quick-change knives.

TORQUE-LIMITING SAFETY CLUTCH

The torque-limiting clutch protects against damage to the drive unit when blockages are caused by foreign objects. Furthermore, the highly precise sensors facilitate the controlled powering down of the machine to preserve all components.

Perfect drive protection

thanks to the drive unit`s instant mechanical disengagement.

Secure power down

with extremely precise sensors.

Fully adjustable

to various materials.