- Home

- Companies

- Lindner-Recyclingtech GmbH

- Products

- Lindner Universo - Model 2800 - ...

Lindner Universo - Model 2800 -Stationary Universal Shredding Machine

UNIVERSAL SHREDDING TO THE EXTREME: ROBUST, RELIABLE AND HIGH THROUGHPUT. The Universo series with its robust, high-quality engineering ensures a long service life with consistently high throughput rates. Whether you are shredding different types of plastic or waste, with its heavy-duty gearbox drive and robust cutting system there is no job that this shredder cannot handle. As has been proven by thousands of operating hours in different fields of application. More info on: www.lindner.com

Lindner`s original: tried and tested a thousand times over, our internal pusher allows for easy and secure machine feeding. Our years of experience and continuous development have left their mark on its distinctive design.

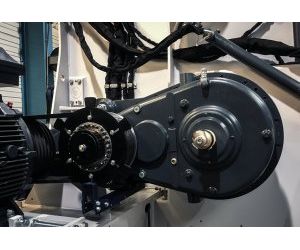

Universo’s tried-and-tested, extremely sturdy drive offers high torque values and excellent performance. Designed for continuous operation, the motor and gearbox ensure that the rotor cutting system rotates 150 times per minute at a nominal capacity of 220 kW.

GLOBAL AVAILABILITY

of all easy-change standard parts.

READILY AVAILABLE

Our easily replaceable standard components are readily available worldwide.

ADAPTS TO THE MATERIAL

thanks to its variable speeds.

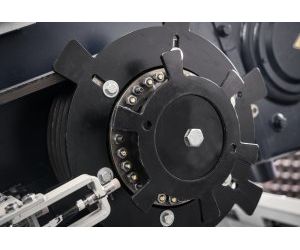

The swivel-mounted, hydraulically operated screen unit allows for easy and comfortable access for maintenance and refitting. The screens are available with various mesh widths and can easily be changed by hand by just one person – so you can quickly customise the shredder to the particle size you need.

EASY ACCESS FOR MAINTENANCE AND FITTING

thanks to the swivel-mounted, hydraulically operated design.

EXTREMELY SAFE OPERATION

with the electromagnetically locked screen access point, preventing access to the cutting chamber while the machine is in operation.

FLEXIBLE OUTPUT SIZES

made possible with screen units in different hole sizes.

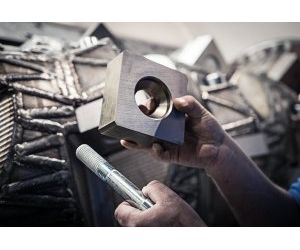

Specifically made for the toughest conditions: these particularly robust cutters and cutter holders make the cutting systems impervious to foreign objects, resulting in a long service lilfe and high output rates. The double cutting counter knives and scrapers as well as the cutting gap that is adjustable during operation let you enjoy continuously high output rates for consecutive processes.

HIGH OUTPUT RATES

even with tough materials.

LOW WEAR AND TEAR COSTS

ensured by fourfold usable, quick-change cutters.

UNDETERRED BY NON-SHREDDABLES

thanks to robust knives and knive holders

The hydraulically operated, inward-opening maintenance door allows you to quickly and safely access the cutting system for maintenance work or swiftly remove foreign objects with minimum material leaks.

REMOVE FOREIGN MATTER QUICKLY AND CLEANLY

with the maintenance door at position 2.

ENJOY COMFORTABLE MAINTENANCE ACCESS

to the knives and counter knives with the maintenance door at position 3.

100% SAFE OPERATION

with the mechanical safety lock and the pusher`s special parking position.

The torque-limiting clutch protects against damage to the drive unit when blockages are caused by foreign objects. Furthermore, the highly precise sensors facilitate the controlled powering down of the machine to preserve all components.

PERFECT DRIVE PROTECTION

thanks to the drive unit’s lightning-speed disengagement.

FULLY ADJUSTABLE

to various materials.

SECURE POWER DOWN

with robust sensors.

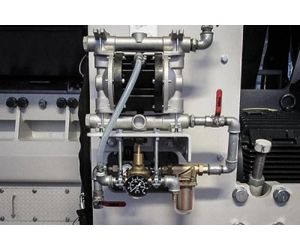

Our optional water sprinkling system to reduce air-borne dust at the filling area offers a central water pipe with four nozzles in the enclosed hopper with suction point which can be easily activated via the control panel or the remote control. The system is designed for year-round use (down to -25°C).

Fire Extinguishing System with Spark Detection

The fire extinguishing system detects sparks and overheated objects, protecting the system when easily flammable materials are being processed. The sensors monitor not only the shredder but also the discharge conveyor and where necessary trigger the extinguishing process. Thanks to the central water supply, the pressure tank is subsequently filled automatically and once again ready for use.

Bus Connection to the External Control System

Thanks to being connected to the control system (Profibus® or Profinet®), status/maintenance messages can be generated directly and the machine operated from the control room.