- Home

- Companies

- Lindner-Recyclingtech GmbH

- Products

- Lindner Urraco - Model 95 - Mobile ...

Lindner Urraco - Model 95 -Mobile Shredding Machine

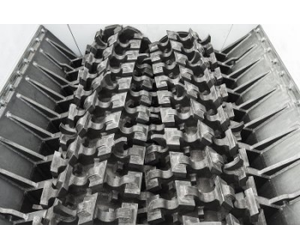

TAKES MOBILE SHREDDING TO THE EXTREME: MAXIMUM OUTPUT; FULL MOBILITY. Thanks to its extremely powerful engine, long working length and aggressive intake, this twin-shaft shredder makes short work of almost every material. Enjoy an extremely reliable, cost-reducing machine with low wear and tear, easy maintenance and low energy consumption. More info on: www.lindner.comThe Urraco 95‘s slow-speed twin-shaft cutting system with cutting tools 70% longer than its smaller brother, the U75, offers aggressive intake and consequently ensures highly efficient shredding processes. Depending on the shaft selected, even the most difficult materials such as railway sleepers and light scrap metal can be processed safely and effectively.

Incredibly productive

thanks to aggressive intake and the extra long shafts.

Adapts perfectly to the material

thanks to shaft pairs available in different designs.

Maximum resistance

with our welded crushers, rippers, scrapers and breaker bars.

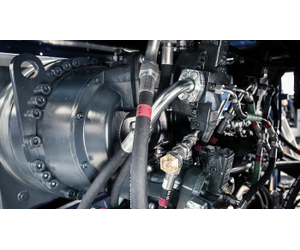

The hydrostatic drive sports self-regulating hydraulics with a maximum torque of up to 480,000 Nm, crushing material powerfully with its shafts.

High output

thanks to the self-regulating hydrostatic double drive.

Safe operation

ensured by the instant detection of non-shreddables.

Effective shredding

with a torque of up to 480,000 Nm and robust planetary gears.

Smart hopper tilting up to 80° on both sides for optimised and even material feeding. The machine can be operated simply from the wheel loader using the optional remote control.

The electrive drive of the Urraco E and Urraco EK models meets the industries demands for energy efficient and powerful shredding options. The Urraco EK model with tracked chassis additionaly offers an independent power unit for a flexible and wireless transfer to the location where it is needed.

with our 240 kW electric engine

Urraco 4000 E

available with base frame and optional heavy duty axle

E-model with tracked chassis and independent power unit

Magnetic Separator of Ferrous Metal

Optionally, a permanent magnet can be fitted above the discharge conveyor. The machine sports a hydraulic drive whose height is fully adjustable via remote control. The magnet comes with an ejector chute and can be folded up together with the discharge conveyor.

Water Sprinkling System

Our optional water sprinkling system to reduce air-borne dust at the filling and discharge areas offers a central water pipe with nozzles in the feed and discharge which can be easily activated via the control panel or the remote control.

Fire Extinguishing System

The fire extinguishing system detects sparks and overheated objects, protecting the motor compartment from fire. The sensors monitor the shredder and where necessary trigger the extinguishing process. The integrated pressure tank douses the fire extremely quickly before any extensive damage can be inflicted.

Visualisation

All operation and status data can be easily transferred to the control room or a mobile tablet and visualised using a Wi-Fi connection. Perfect for visualisation in the wheel loader during feeding.