- Home

- Companies

- Dragon Water Technologies Ltd (DWT)

- Products

- dynaBLEND - Model L4S-1200-5.OPS - ...

dynaBLEND - Model L4S-1200-5.OPS -Liquid Polymer Blending System

Simply the Best Polymer System Available: dynaBLEND L Series systems are designed to easily accept a wide range of flexible features and options. All dynaBLENDs utilize only the finest components, are built on all stainless-steel frames and are designed to stand the test of time in extreme conditions and harsh environments.

- All Piping Components Rigidly Mounted to Skid

- Gusseted Uprights for Rigidity

- NEMA 4X FRP Control Panel. Fluid Dynamics is a ULC-Certified Panel Shop3

- Control Panel at Operator Eye-Level

- Open Frame Design for Ease of Accessibility Constructed of 304-SS

- Sealtite for All Power Wiring

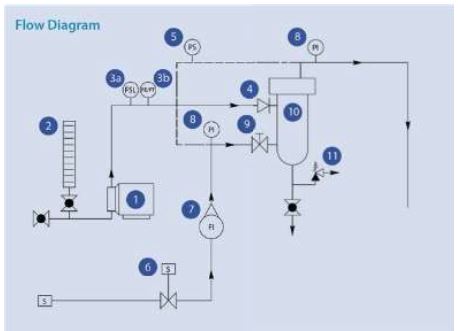

- Metering Pump

- Calibration Column

- Loss of Polymer Flow Switch

- Polymer Flow Measurement (optional)

- Proprietary Design Polymer Check Valve

- Differential Pressure Switch

- Solenoid Valve

- Water Flow Measurement2

- Liquid Filled SS Pressure Gauges

- Variable Orifice Water Control Valve

- dynaBLEND Mixing Chamber

- Pressure Relief Valve

- Can be peristaltic or progressing cavity.

- Can be Rotameter, Turbine Flow Meter or Magnetic Flow Meter.

- Optional stainless-steel panels. Controls also available for hazardous locations.

In twenty years of independent side-by-side trials, the dynaBLEND™ system has proven itself superior to alternative blending methods. Success is due to its patented, non-mechanical Hydro Action Technology— a technology that produces in excess of six times the mixing energy per unit volume than a comparable sized mechanical mixer.

dynaBLEND induces high mixing energy without the use of mechanical impellers to ensure a blending process free from polymer damage, while preventing polymer gelling. Preventing polymer gelling or damage maximizes your polymer investment by reducing your polymer use. Thousands of installations worldwide validate dynaBLEND’s track record for superior performance and reliability.

Action Stage 1

Initial Ultra-High Energy:

A pressure drops occurring across the specially designed variable orifice water control valve produces a high-velocity water jet. This water jet, traveling at approximately 21.3 m (70 ft) per second, is aimed directly at, and impinges on the polymer as it enters the mixing chamber. At this point, the only point where high energy exists in the mixing chamber, the polymer is coiled up and not susceptible to damage

Stage 2

Recirculation:

In dynaBLEND’s concentric mixing chambers, newly blended polymer recirculates multiple times for additional exposure to non-damaging turbulence, completing the blending process. This recirculation ensures that polymer solution is present directly after the point of neat, concentrated polymer injection, for an ideal activation and blending environment.

Stage 3

Diminishing Mixing Energy:

Mixing energy naturally diminishes in dynaBLEND’s concentric chambers. The flow path through the system’s concentric chambers further ensures optimum polymer performance by preventing polymer from short-circuiting the three-stage process.