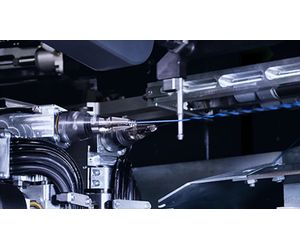

Komax Sigma - Model 688 LTT -Low Torsion Twisting Wire Processing Machine

Manufacture UTP cables with the new LTT (low torsion twisting) quality standard using proven Komax technology within the Sigma family. Data transfer rates below 100 Mbit/s will become just as important in the future as those at the upper end of the gigabit range. Today''s challenge of producing a UTP in a stable manner to ensure a transfer rate of 10 Mbit/s will probably become the norm in the future. To ensure the required quality of data transfer, a stable physical cable is necessary. As the mechanical properties are directly reflected in the electrical properties, reliable and stable production on demand is of utmost importance. A constant and continuous lay length, a compact and tight helix, as well as precise dimensional accuracy in the lengths of the individual wires result in a highly stable impedance and minimal delay time differences in the twisted cable. Processing techniques such as twisting with back-twisting make it possible to produce a UTP from two single wires on a twisting machine directly on site in the factory – a twisted cable for the demanding data transfer of tomorrow.

Smart mode: eliminates operator influence

Smart mode reduces operator influence and therefore increases production quality.

The LTT process developed and patented by Komax achieves a new standard of quality in the production of UTP cables.

Fully automatic production of 0.13 mm² UTP cables, according to OEM specifications and without operator influence.

Sigma 688 LTT

Metric

- Wire length, processing on both sides min.: 300 mm

- Wire length max.: 7000 mm

- Strip length side 1 min. (Processing set for short open ends): 0.1 mm

- Strip length side 1 max. (Processing set for short open ends): 18 mm

- Strip length side 2 min. (Processing set for short open ends): 0.1 mm

- Strip length side 2 max. (Processing set for short open ends): 28 mm

- Strip length side 1 min. (Processing set for open ends, standard): 0.1 mm

- Strip length side 1 max. (Processing set for open ends, standard): 18 mm

- Strip length side 2 min. (Processing set for open ends, standard): 0.1 mm

- Strip length side 2 max. (Processing set for open ends, standard): 35 mm

- Wire cross section min. (Processing set for short open ends): 2 × 0.13 mm²

- Wire cross section max. (Processing set for short open ends): 2 × 0.5 mm²

- Wire cross section min (Processing set for open ends, standard): 2 × 0.13 mm²

- Wire cross section (Processing set for open ends, standard): 2 × 0.5 mm²

- Wire cross section min. (Processing set for long and different ends on side 1): 2 × 0.5 mm²

- Wire cross section max. (Processing set for long and different ends on side 1):

- Open wire ends min. (Information without end processing, processing set for short open ends): 15 mm

- Open wire ends max. (Information without end processing, processing set for short open ends): 99 mm

- Open wire ends min. (Information without end processing, processing set for open ends, standard): 30 mm

- Open wire ends max. (Information without end processing, processing set for open ends, standard): 99 mm

- Open wire ends min. (Processing set for long and different ends on side 1): 30 mm

- Open wire ends max. (Processing set for long and different ends on side 1): 125 mm

- Lay length min.: 5 mm

- Lay length max.: 50 mm

- Lay length accuracy: Accuracy: ±10%, max. 2mm per pitch on average over 10pitches

- Spot tape position: Last intersection point (default position) of 0.0mm - 80mm in direction of center of wire

- Wire draw-in speed: 5 m/s

- Length accuracy: ± 0.1% + 1 mm

- Length accuracy: ± 0.1% + 1 mm

- Seal diameter max. (Processing set for short open ends): 5.5 mm

- Seal length max. (Processing set for short open ends): 11 mm

- Noise level (without crimp modules) max.: 80 dB

- Electrical connection: 3 × 208 - 480V, 50 - 60Hz, 10kVA

- Wire protection/ground: 32

- Compressed-air connection: 5 – 8 bar

- Air consumption (depending on configuration) min.: 5.5 m³/h

- Air consumption (depending on configuration) max.: 13.2 m³/h

- Network connection: Ethernet

- Recommended operating pressure ±0.5bar/7.25psi: 6 bar

- Operation outside the recommended operating pressure: Non-compliance with the recommended operating pressure can prevent peripheral devices from functioning completely correctly. Please also observe the technical data for peripheral devices. The maximum permitted operating pressure depends on the ambient temperature: 6.5 bar to 40 °C/6 bar at 40 °C and above

- Weight (approx.): 3400 kg

- Length: 11511 mm

- Width: 1780 mm

- Height (with safety cover closed): 1985 mm

- Height (with safety cover open): 2865 mm

- Dimension Twister: 7 m

- Minimum clearance around equipment for maintenance work: 1500 mm

- Floor load capacity: 500 kg/m²

- Floor conditions: Flat, stable, clean and vibration-free support surfaces. The support surface for machine load points must be a continuous base plate of concrete. No expansion joints between machine load points. Support surface non-slip. No plastic or asphalt coatings.

- Ambient temperature min.: 10 °C

- Ambient temperature max.: 45 °C

- Humidity, non-condensing: 30 – 90 %

- Processing outside the specifications: Processing outside the specifications upon request. In case of doubt, we will be happy to provide processing samples for your wires.

- Producible parameters: ** Producible parameters depend on pitch, outer diameter, and end processing. Producibility can be verified using the producibility check software or with a feasibility test.

Imperial

- Wire length, processing on both sides min.: 11.8 in

- Wire length max.: 275.6 in

- Strip length side 1 min. (Processing set for short open ends): 0.004 in

- Strip length side 1 max. (Processing set for short open ends): 0.7 in

- Strip length side 2 min. (Processing set for short open ends): 0.004 in

- Strip length side 2 max. (Processing set for short open ends): 1.1 in

- Strip length side 1 min. (Processing set for open ends, standard): 0.004 in

- Strip length side 1 max. (Processing set for open ends, standard): 0.7 in

- Strip length side 2 min. (Processing set for open ends, standard): 0.004 in

- Strip length side 2 max. (Processing set for open ends, standard): 1.4 in

- Wire cross section min. (Processing set for short open ends): AWG26

- Wire cross section max. (Processing set for short open ends): AWG20

- Wire cross section min (Processing set for open ends, standard): AWG26

- Wire cross section (Processing set for open ends, standard): AWG20

- Wire cross section min. (Processing set for long and different ends on side 1): AWG20

- Open wire ends min. (Information without end processing, processing set for short open ends): 0.59 in

- Open wire ends max. (Information without end processing, processing set for short open ends): 3.9 in

- Open wire ends min. (Information without end processing, processing set for open ends, standard): 1.2 in

- Open wire ends max. (Information without end processing, processing set for open ends, standard): 3.9 in

- Open wire ends min. (Processing set for long and different ends on side 1): 1.2 in

- Open wire ends max. (Processing set for long and different ends on side 1): 4.9 mm

- Lay length min.: 0.2 in

- Lay length max.: 3.2 in

- Lay length accuracy: Accuracy: ±10%, max. 0.08 in per pitch on average over 10pitches

- Spot tape position: Last intersection point (default position) of 0.0in - 3.1 in in direction of center of wire

- Wire draw-in speed: 16.4 ft/s

- Length accuracy: ± 0.1% + 0.04 in

- Seal diameter max. (Processing set for short open ends): 0.22 in

- Seal length max. (Processing set for short open ends): 0.43 in

- Noise level (without crimp modules) max.: 80 dB

- Electrical connection: 3 × 208 - 480V, 50 - 60Hz, 10kVA

- Wire protection/ground: 32

- Compressed-air connection: 73 – 116 psi

- Air consumption (depending on configuration) min.: 194.2 ft³/h

- Air consumption (depending on configuration) max.: 466.2 ft³/h

- Network connection: Ethernet

- Recommended operating pressure ±0.5bar/7.25psi: 87 psi

- Operation outside the recommended operating pressure: Non-compliance with the recommended operating pressure can prevent peripheral devices from functioning completely correctly. Please also observe the technical data for peripheral devices. The maximum permitted operating pressure depends on the ambient temperature: 6.5 bar to 40 °C/6 bar at 40 °C and above

- Weight (approx.): 7496 lb

- Length: 453.2 in

- Width: 70.1 in

- Height (with safety cover closed): 78.1 in

- Height (with safety cover open): 112.8 in

- Dimension Twister: 275 in

- Minimum clearance around equipment for maintenance work: 59 in

- Floor load capacity: 500 kg/m²

- Floor conditions: Flat, stable, clean and vibration-free support surfaces. The support surface for machine load points must be a continuous base plate of concrete. No expansion joints between machine load points. Support surface non-slip. No plastic or asphalt coatings.

- Ambient temperature min.: 50 °F

- Ambient temperature max.: 113 °F

- Humidity, non-condensing: 30 – 90 %

- Processing outside the specifications: Processing outside the specifications upon request. In case of doubt, we will be happy to provide processing samples for your wires.

- Producible parameters: ** Producible parameters depend on pitch, outer diameter, and end processing. Producibility can be verified using the producibility check software or with a feasibility test.