- Home

- Companies

- Containment Solutions, Inc., (CSI)

- Products

- CSI - Manholes or Lift Stations

CSI - Manholes or Lift Stations

Wetwells, or lift stations, are used to move sewage from lower to higher elevation, particularly where the elevation of the source is not sufficient for gravity flow or when the use of gravity alone will result in excessive excavation and higher construction costs.

Fiberglass wetwells eliminate infiltration and exfiltration at this critical station in a sanitary sewer line. The monolithic construction of the wetwell has no sidewall joints, sections or seams to let ground water in or waste out. And because they are highly resistant to corrosion, you are assured that wetwells will provide long lasting performance.

Sizes range up to 20′ diameter from our various manufacturing facilities across the nation. CSI wetwells are a convenient, long-lasting and cost effective alternative to traditional concrete structures and each come with an industry leading 20-year structural and corrosion warranty.

Flowtite Fiberglass Wetwells were developed over twenty-five years ago. Since then, thousands of our wetwells have been installed in the U.S.A., in many different types of soil, and in many different effluents, without a single failure. Flowtite Wetwells have stood the test of time.

This should not be surprising. Flowtite Fiberglass Wetwells have the corrosion resistance, strength, monolithic design, and lightweight, which make them ideal for any wastewater application. Flowtite Fiberglass Wetwells put an end to worry about infiltration/exfiltration at this critical station in a sanitary sewer line. The monolithic construction of the Flowtite Wetwell has no sidewall joints, sections or seams to let ground water in or waste out. And because it is highly resistant to corrosion, you’re assured that Flowtite Wetwells will provide long-lasting performance.

We use only the finest quality resin and glass. Plus, we add chemically enhanced silica to improve corrosion resistance, strength, and overall performance. These materials are then centrifugally cast to form the very best wetwell available today.

Flowtite is a name you can trust. Formerly a division of Owens-Corning, the world’s largest fiberglass producer, we are committed to continuing our tradition of excellence. After all, we have been manufacturing underground tanks and wetwells for over twenty-five years and we want to continue to earn your trust, just as we have for over a quarter of a century.

- Corrosion resistance

- Structural strength

- Lightweight

- Monolithic design

- 20-year corrosion and structural warranty

- Designed per ASTM D 3753

- PVC pipe stubouts

- Fiberglass pipe stubouts

- Fiberglass watertight bottoms

- Fiberglass tops with square or round top opening

- Top and bottom flanges

Eliminates Corrosion and Eliminates Costly Maintenance/Rehabilitation

Corrosion is the mortal enemy of wetwells, but not of Flowtite fiberglass. Even decades of attack by hydrogen sulfide has no effect on Flowtite Wetwells. As a result, you avoid the service disruption and costly repairs and maintenance associated with ordinary wetwells.

Structurally Sound - Exceeds H-20 Load Rating

Fiberglass wetwells have been in service for more than twenty-five years. Some of these installations are in streets. Flowtite wetwells can be installed in traffic locations. Flowtite wetwells are designed to meet or exceed the requirements of ASTM D 3753. They can be installed in a variety of soil conditions. Each wetwell is designed to withstand the hydrostatic head to grade with the wetwell completely empty.

Ease of Installation

Flowtite wetwells are far lighter than concrete – about 125 pounds per vertical foot. The light weight of the Flowtite wetwell combined with its one-piece construction, provide the contractor with one-step installation. Completely constructed at the factory, Flowtite wetwells eliminate time-consuming concrete forms or multiple pre-cast concrete sections.

Reduce Infiltration

In most cases, ordinary concrete wetwells are installed in sections; otherwise they would be too heavy to move. This creates a joint – the source of most leaks – every three feet. Flowtite wetwells have no joints. They are available in standard one-piece lengths from 3 to 35 feet. This prevents infiltration or exfiltration. The monolithic design also makes installation easier by reducing the time necessary to complete joints between sections.

Will Not Float

Flowtite fiberglass wetwells have a better Safety Factor against float-out than concrete wetwells. The Flowtite fiberglass wetwell has a wall thickness far less than concrete wetwells, resulting in a decrease in volume displacement of the unit. As a result, the buoyant forces on Flowtite fiberglass wetwells are less than concrete wetwells.

Watertight Construction

Flowtite Wetwells are made in one integral piece – up to 35’ in length – to prevent infiltration and exfiltration. With no sidewall joints, seams, or sections to let groundwater in or wastewater out, Flowtite Wetwells provide a virtually leakproof answer to deteriorated concrete wetwells.

Non-Corrosive Construction Make Flowtite Wetwells Virtually Impervious to Wastewater Conditions

Flowtite Fiberglass Wetwells are suitable for use in storm, industrial and sanitary sewers with a temperature range of 40°F to 150°F. Because they are constructed of glass fiber reinforced polyester resin, they are virtually inert to corrosion from sewage, sewage gases, corrosive soils or stray electrical currents. And, in contrast to concrete, Flowtite Wetwells are unaffected by hydrogen sulfide. Over 400 chemical environments have been approved for use with Flowtite Wetwells. Your Containment Solutions representative can give you more information concerning use of this product in corrosive conditions.

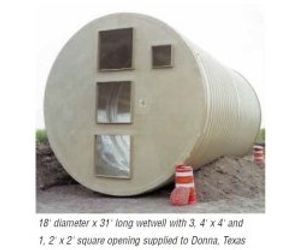

Sizes

Wetwells are available in lengths from 3 to 35 feet and are manufactured as one integral piece. Wetwells are available in 3’ to 20’ diameters. Longer wetwells can be custom fabricated. Ask your CSI representative for details.

Fiberglass Flat Tops and Bottoms

Fiberglass flat tops provide a corrosion barrier for the top concrete slab. Fiberglass tops are designed to allow the contractor to place forms and the hatch cover on the unit and make one pour for the top concrete slab. The opening can be rectangular or round. A vapor barrier up to 4" high is standard around the opening. Fiberglass bottoms are watertight to reduce infiltration/exfiltration and withstand the hydrostatic load with water to grade and the unit completely empty. All structural reinforcements utilize pultruded fiberglass members to ensure adequate and consistent safety factor over the design life of the unit.

Piping Connections

Piping connections can be made with factory installed PVC pipe or fiberglass host sleeves that are sized to accept the incoming pipe. The annular space of the piping is sealed using a mechanical seal such as Inner-Lynx or Link- Seal. Other connections available are Inserta-Tee fittings, PVC stubouts and resilient rubber boot connectors.

Specification Compliance

The Flowtite Wetwell meets or exceeds all requirements of ASTM specification D3753 for Glass Fiber-Reinforced Polyester Manholes and Wetwells.