Shanghai Techase Environment Protection Co., Ltd

- Home

- Companies

- Shanghai Techase Environment Protection ...

- Products

- Techase - Membrane Bioreactor (MBR)

Techase - Membrane Bioreactor (MBR)

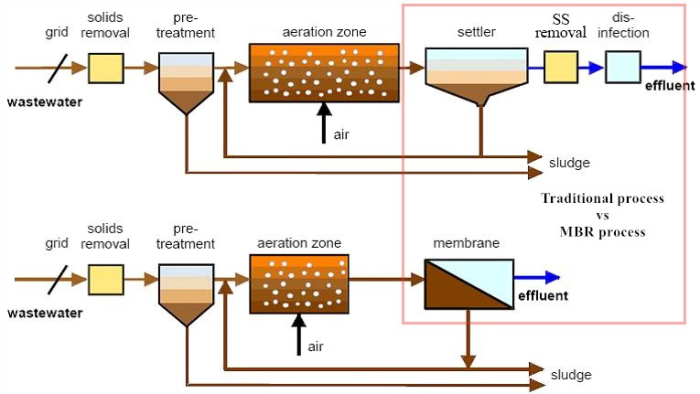

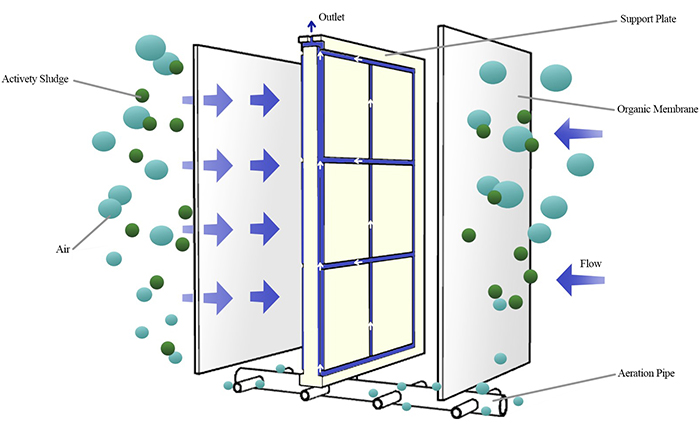

Membrane Bioreactor: refers to a new type of wastewater treatment process that combines biological reaction with membrane separation, uses membrane as a separation medium instead of conventional gravity sedimentation to obtain effluent, and can change the reaction process and improve the reaction efficiency.

Most popular related searches

membrane bioreactor

activated sludge treatment

wastewater treatment system

suspended solids removal

sewage treatment system

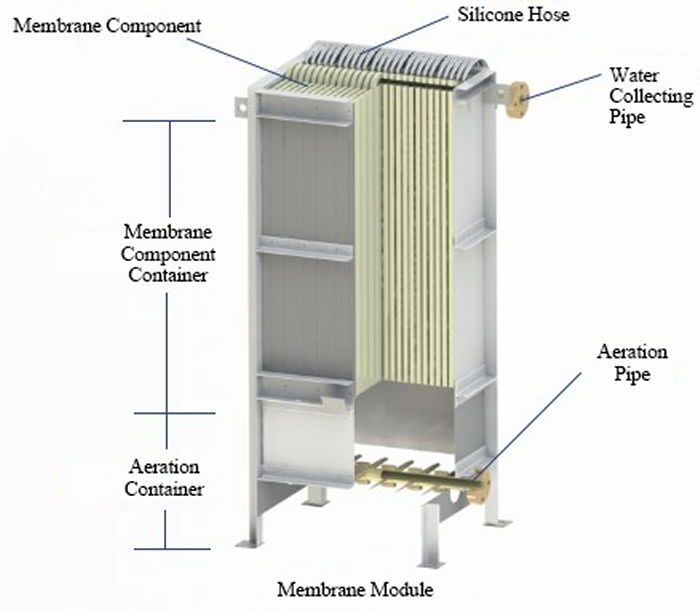

membrane module

activated sludge

activated sludge system

membrane separation

sludge treatment

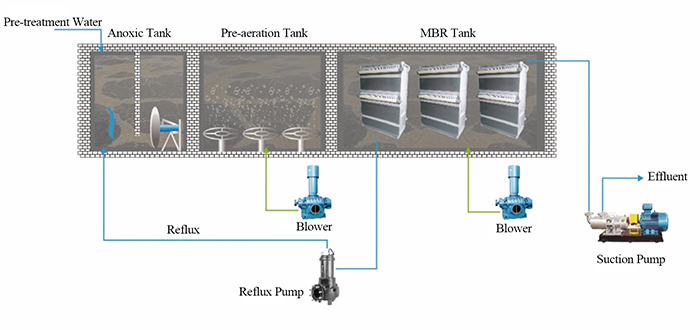

- Small footprint, flexible operation and strong adjustability;

- Low operating cost, strong impact resistance of the system, and low sludge volume;

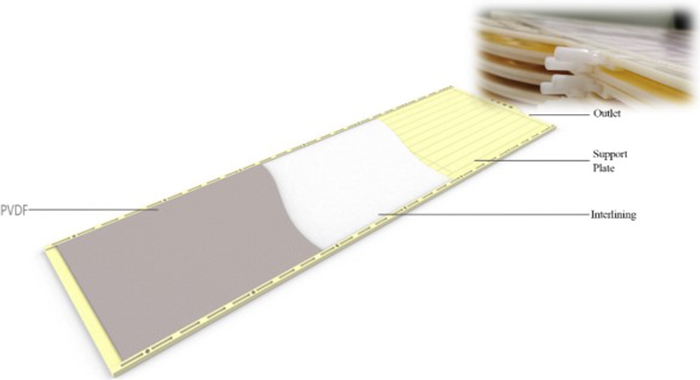

- Membrane module is pollution resistance, anti-fading, and easy to clean and recover of membrane module;

- Membrane pores are evenly distributed, high quality of the effluent, high throughput, and not easy to block.

Membrane Bioreactors (MBR) combine conventional biological treatment (e.g. activated sludge) processed with membrane filtration to provide an advanced level of organic and suspended solids removal.

- High quality and stability effluent: the high-efficiency separation effect of the membrane is much better than that of the traditional sedimentation tank. The effluent is extremely clear, suspended solid and turbidity are close to zero.

- Treatment efficiency improved: microorganisms are completely trapped in the reactor, the system maintains a high microbial concentration, increases the volume load, improves the efficiency of pollutant removal, and has a strong bearing capacity for impact loads.

- Nitrification ability enhanced: microorganisms are completely trapped in the reactor, which is conducive to the growth of long-generation nitrifying bacteria, and has extremely high nitrification efficiency.

- Biochemical reaction enhanced: Extend the residence time of refractory organics in the system, microorganisms are completely trapped in the reactor, improve biodiversity, facilitate the preservation of special bacteria, increase the possibility of refractory organics being degraded, and improve refractory organic degradation rate.

- Sludge production reduced: can be operated under high volume loads and low sludge loads, biological reactions are in the endogenous breathing period, and the remaining sludge production is low, reducing sludge treatment costs.

- Convenient operation and management: hydraulic retention time (HRT) and sludge retention time (SRT) are completely separated, the operation control is more flexible and stable, and it is easy to realize automatic control.

- Footprint reduced: MBR can be used to reduce the footprint of an activated sludge sewage treatment system by removing some of the liquid component of the mixed liquor.