Sesotec GmbH

- Home

- Companies

- Sesotec GmbH

- Products

- Sesotec - Metal Detection Systems for ...

Sesotec - Metal Detection Systems for Pneumatic Conveyance

FromSesotec GmbH

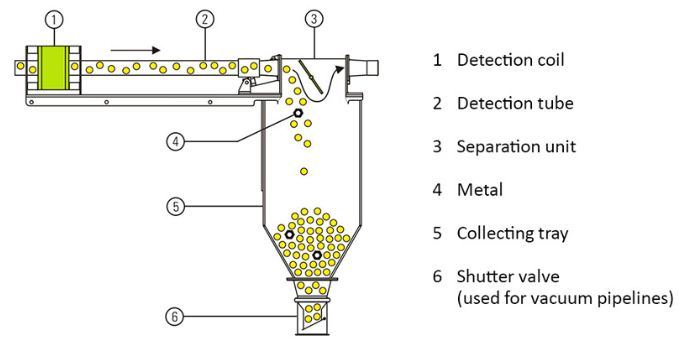

Metallic contaminants in plastic granulate, regrind, flour or breadcrumbs can lead to blocked nozzles and filters, damaged machines or impure final products. Our metal detectors for pneumatic applications provide optimum protection against interruptions to production, downtime and customer complaints. Our metal detection systems can be integrated quickly and easily into existing vacuum or pressure conveyor pipes. Even at high conveying speeds and temperatures, they reliably remove contaminants from pneumatically conveyed bulk goods with minimal loss of material for the plastics-processing, chemical, pharmaceutical and food industries.

Most popular related searches

metal detection system

metal detection

pneumatic conveyor

plastic granulate

pipe system

plastic granulator

plastic processing

contaminants removal

plastic regrinds

pressure pipe

- Easy to use

- Highest detection accuracy

- Easy cleaning and maintenance

- Easy installation

- Thanks to quick-lock couplings and flanges, our metal detectors are extremely easy to integrate into piping systems, regardless of whether they are positioned vertically, horizontally or at an angle.

- They remove metallic contaminants without interrupting the flow of the conveyed material or reducing the conveying speed.

- They function reliably even at high conveying speeds and temperatures.

- The two-channel technology provides the highest sensitivity to all metals, regardless of whether they are magnetic or not, even when they are embedded in the product.

- Digital signal processing guarantees optimum security in line with EU directives.

- Preset operating parameters mean the control units are extremely easy to operate.

- An exportable, password-protected system logbook or the option of directly connecting to the company network ensures the necessary exchange of data.

- Our metal detection systems feature an auto-learn function to best compensate for the intrinsic conductivity of the inspected material.

- ATEX-compliant versions up to zone 20 are available.