- Home

- Companies

- Sesotec GmbH

- Products

Sesotec GmbH products

Metal Detection Systems

Sesotec - Metal Detectors for Conveyor Belts and Chutes

Regardless of whether you manufacture or process food, plastics or other products, our tunnel and flat metal detectors readily integrate into all production lines for piece and bulk goods. Once installed there, they help reliably protect consumers and machines from metallic contaminants. Tunnel metal detectors enclose a conveyor belt, while flat metal detectors are attached underneath conveyor belts or chutes. They detect metallic contaminants, regardless of metal type and whether the contaminant is exposed or embedded in the product.

Sesotec - Metal Detection Systems With Integrated Conveyor Belt

Safely free of metallic contaminants – piece by piece. Our tunnel metal detectors for conveyor belt use enable you to detect metallic contaminants in piece goods and separate out affected products quickly and reliably. The most effective protection for consumers, your machines and your image. Metal detectors with integrated conveyor belt are all-in-one systems consisting of a tunnel metal detector, a conveyor belt and optional reject mechanisms. They can be integrated without issue into existing production lines. Our systems provide robust and hygienic conveyor belt technology, together with ultra-precise metal detection and extremely easy handling. The modular design allows for custom solutions tailored to you and your products.

Sesotec - Metal Detection Systems for Liquids and Pastes

The food industry has to meet the highest quality standards. Regardless of whether you produce sausage meat, processed cheese, marmalade, mustard or soups, our metal detectors will help you reliably protect machines and consumers from metallic contaminants. What is more, they are extremely easy to integrate into your production lines. Our metal detection systems for liquid and paste products can be quickly and easily integrated into existing piping systems and connected to all common vacuum fillers, pumps, clipper machines and sausage-filling machines. Thanks to different separation systems to choose from, they ensure the safe and efficient removal of all metallic contaminants.

Sesotec - Metal Detection Systems for Pneumatic Conveyance

Metallic contaminants in plastic granulate, regrind, flour or breadcrumbs can lead to blocked nozzles and filters, damaged machines or impure final products. Our metal detectors for pneumatic applications provide optimum protection against interruptions to production, downtime and customer complaints. Our metal detection systems can be integrated quickly and easily into existing vacuum or pressure conveyor pipes. Even at high conveying speeds and temperatures, they reliably remove contaminants from pneumatically conveyed bulk goods with minimal loss of material for the plastics-processing, chemical, pharmaceutical and food industries.

Magnet Systems

Sesotec - Magnet Systems for Liquids and Pastes

The food, pharmaceutical and chemical industries all have the highest demands when it comes to product quality. Our magnet separators have been specifically designed to meet their requirements. The separators integrate without issue into existing conveyor pipes and reliably protect consumers from magnetic metal contaminants. Filter magnets for liquid and paste products integrate into pressure conveyor pipes. They remove minute magnetic metal contaminants from the goods that flow through.

Sesotec - Magnet Systems for Material Columns

Our magnet separators have been specifically designed for use in the plastics industry and can be integrated quickly and easily into columns of granulated material. They are installed shortly before or right in front of the material inlet of injection-moulding machines, extruders and blow-moulding machines, for example. By safely removing ferromagnetic particles, the separators provide highly effective protection against plant downtime and costly repairs. Our magnet systems for material columns integrate into piping systems, including existing ones. Once installed, they remove minute magnetic metal particles from the bulk goods that pass through.

X-ray Inspection Systems

Sesotec - X-Ray Inspection Systems for Packaged Products

Our X-ray systems for packaged piece goods have been specifically designed for use in the food industry and are mostly deployed for end-of-line quality control purposes. They combine highly efficient contaminant detection with the greatest ease of operation and a hygienic design, and they comply with all key standards in the food industry. X-ray inspection systems not only detect metals, but also many other contaminants, such as glass, ceramic, stones, raw bones and PVC, not to mention a variety of product defects. All of this means precise end-of-line inspection and reliable protection against customer complaints and recalls.

Sorting Systems

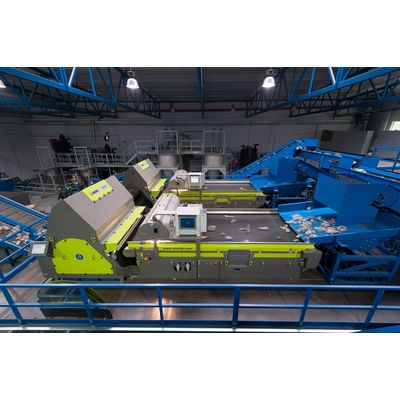

Sesotec - Recycling Sorting Systems with Conveyor Belt

Our recycling sorting systems with conveyor belt are true all-rounders. They separate household waste just as precisely and effectively as plastics, glass, scrap metal and electrical waste. The modular design makes it possible to custom combine various sensors. Recycling sorting systems with conveyor belt are suitable for sorting mixed, piece or shredded materials. Sesotec offers machinery designed specifically for one purpose as well as universal multi-sensor systems that are able to process different types of material. Our multi-sensor sorting systems divide mixed material flows into uniform fractions and thereby help to profitably introduce recycled materials back into the production cycle. Different sensors can be used for this purpose, depending on the application: colour and shape sensors, metal sensors or near-infrared sensors (please refer to the different versions and configurations as well).

Sesotec - Recycling Sorting Systems with Chute

Do you recycle plastics or glass? Are looking for an economical way to sort these material flows? Our recycling sorting systems with inlet chute efficiently separate mixed materials and remove contaminants with precision. Sesotec recycling sorting systems with chute are suitable for removing contaminants or impurities from material that has already been shredded. They sort plastic flakes and regrind as well as glass fragments. Sesotec offers machinery designed specifically for one purpose as well as universal multi-sensor systems for various sorting jobs.