- Home

- Companies

- PDC Machines Inc.

- Products

- Metal Stirred Reactors

Metal Stirred Reactors

PDC Machines constructs metal stirred tank reactors and pressure vessels from most machinable alloys. Capacities range from 1 liter to 50 gallons (189 liters). Agitated ctsr reactor design pressures range from full vacuum to 100,000 psig (6,394 barg). Temperatures up to 932 °F (500 °C).

Each continuous stirred reactor is a complete system. This includes the reactor vessel, supporting stand, agitation assembly (magnetic stirrer, drive motor, belt, belt guard, impeller and digital tachometer), multiple process connections, drain, sample tube, temperature sensor, cooling coil and rupture disc assembly. Heating system and controls are optional.

We offer a complete skid mounted stirred reactor system complete with product loading, feed, reaction and receiving modules, mass balance and product analysis. We also offer a variety of controls from simple manual controls to advanced PC-based SCADA and DCS. Please refer to our pilot plant section for additional information.

Interested in a quote on a PDC Machines stirred reactor? Please use our Stirred Reactor and Pressure Vessel Selection Guide to help you specify your stirred reactor or pressure vessel.

Our clients include Air Products & Chemicals, Akzo Nobel Chemicals, Bayer Corp, The Dow Chemical Co., Chevron Phillips Chemical Co., Celanese Chemicals, Cook Composites & Polymers, E.I. Du Pont, BASF, ExxonMobil Chemical Co., General Electric Corporate R&D, International Specialty Products, Omnova Solutions, Penford Products Co., PQ Corp, Rohm & Haas, Sartomar Co., Witco Chemical Corp., W.L. Gore & Associates, Saudi Arabia Basic Industries (SABIC), and others.

PDC Machines has long been a trusted manufacturer of metal and glass reactors. We offer a wide selection of agitated reactors and accessories including laboratory, bench top and bench scale reactors to meet the changing needs of laboratories, pilot-plants and small-scale production facilities around the world. Our talented staff of multi-disciplined engineers are highly experienced in the fields of mechanical, and electrical engineering including the latest in information technologies. We team up with each client to design the most cost-effective stirred reactor system that meets every condition. By consistently exceeding our customers expectations PDC Machines has earned a reputation for solving unique and challenging application requirements.

PDC Machines offers the best selection of reactors in the industry

- Reactors constructed from stainless steel or other corrosion resistant alloys.

- Quick-opening covers, bolted, screw-cap, and self-energizing closures.

- Manual and air operated flush ram or ball drain valves, flanged valves or threaded; as well as custom made options.

- Sampling ports, feeds, vent connections and windows are sized as needed.

- Precise temperature control using electric mantle heaters or jacketed vessels.

- Mechanical or magnetically driven mixers with a selection of impellers.

- Sampling tubes, pressure and temperature measurement instruments and sophisticated micro-processor controls with data acquisition packages.

- Other Accessories: Pressure gauges and/or pressure transducers; moving or stationary temperature probes; level sensors; PH meters; sight glass; sparge rings; filtration and clean in place devices; as well as many other modern components.

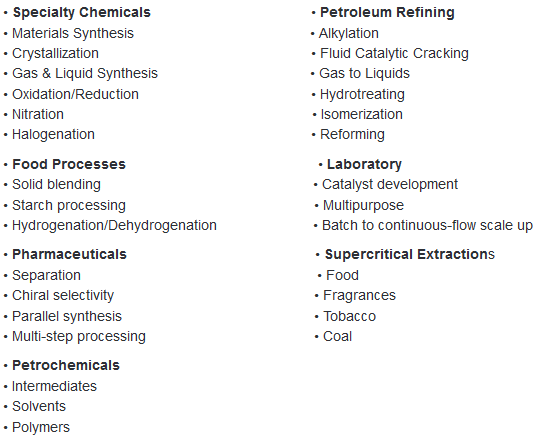

PDC Machines has helped companies develop and capitalize on technical innovation and react quickly to new market opportunities. We provide our clients with chemical reactors including catalyst and catalytic reactors vessels featuring leading-edge technology for research and production in industries including: