- Home

- Companies

- Mitsubishi Hitachi Power Systems, Ltd. ...

- Products

- MHPS - Enhanced All Dry Scrubber System

MHPS - Enhanced All Dry Scrubber System

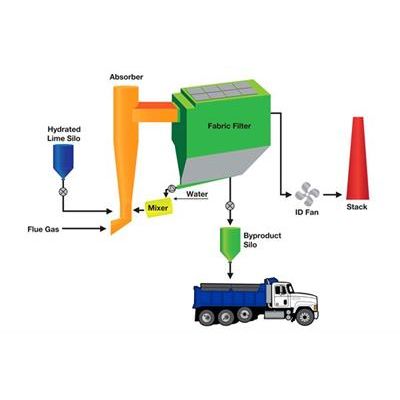

The Mitsubishi Hitachi Power Systems Enhanced All-Dry (EAD™) scrubber is a simple and flexible technology for multi-pollutant control. Obtained through a license agreement with Solios Environment (formerly Procedair), this patented dry scrubber technology was developed in the 1980s and is the original “Enhanced” All-Dry process. The process employs an entrained flow absorber, lime/ash humidifying mixer and our fabric filter technology to effectively remove pollutants in utility applications to meet new MATS / CSAPR requirements. We are applying the EAD™ scrubber technology using a modular approach which provides both greater operating flexibility and reliability.

Simple and Reliable Process

- Reaction occurs in an entrained flow vertical duct with no internals, which is preferred over the more complex fluidized bed processes.

- Reliable, proven equipment with low maintenance

External Reagent Humidification

- Enhances system reliability by separating reagent humidification and sulfur capture steps. No slurry preparation, no wall build-up.

Multi-pollutant Control

- Meet U-MACT (MATS) requirements of mercury, HCl and PM as well as SO2, and SO3/SAM

Modular Design

- Allows unlimited scrubber capacity and wide turndown capability and enhances system layout flexibility.

Low Pressure Drop and Power Consumption

How Does Enhanced All-Dry Scrubber Work?

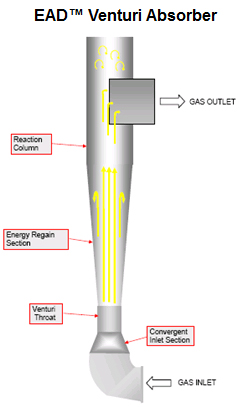

- Entrained flow absorber– no fluidized bed

- Venturi nozzle – promotes turbulence / mixing

- Humidified ash and lime – enhances reactions on sorbent surface and cools flue gas to optimum reaction temperature

- Solids recirculation – produces very high apparent stoichiometric ratio

- Vertical column - additional reaction time and complete drying

- Fabric filter – collection, additional reaction, recycle