Neroxis - Model MTCS 2200 -Gas -Micro Thermal Conductivity Sensor for Gas

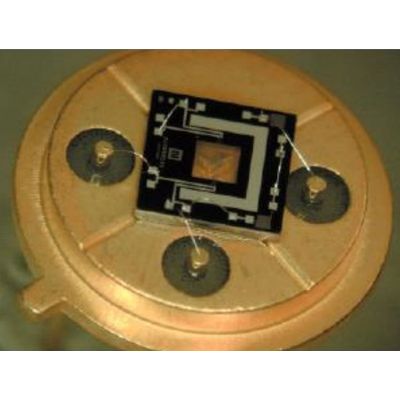

The thermal conductivity gas sensor is manufactured on silicon with thin film deposition and silicon micro-machining techniques. This device determines gas concentrations of binary or ternary gas mixtures. The sensor structure consists of an integrated heater located on a thin electrical and thermal insulating membrane. Two thin film resistors are used for heating and measuring the temperature Tm of the membrane. Two reference resistors are integrated on the silicon beside the membrane area for the compensation of the ambient temperature changes. The four resistors are passivated to protect them from the effects of the gas and are electrically connected to a TO8 or TO5 base by gold wire bonding.

The sensor is attached to a silicon support which also permits gas exchange to the lower side of the membrane. The upper side or the lower side of the membrane is a micro-structure consisting of a cavity anisotropically etched in silicon. The hollow space thus formed between the membrane and the colder part is the gas thermal conductivity measuring section. The measured gas diffuses into the cavity above the heated membrane through the lateral opening, preventing flow perturbation. The thermal heat transfert of the sensor will depend on the thermal conductivity of the gas surrounding the membrane. A constant current circuit is generally used with such sensors for gas measurement. The gas concentration directly depends on the temperature difference [T=Tm – Tamb] which is measured using the electrical power variation.

- Typical heating power: < 6 mW

- Membrane excess temperature: 50 - 70 °C

- Geometry factor, G: 3.9 x 10-3

- Thermal time constant: < 100 ms

- Gas/Humidity responsel time: < 10 s

- Silicon micromachined sensor with very small dimensions (3.5 x 3.5 mm2) and for miniature gas volume (20 mm3)

- Short time constant (membrane time constant <5 ms)

- Low power, highly sensitive with a minimal heating power (< 6 mW)

- Independent of flow

- Integrated sensing resistance on membrane as well as temperature compensation resistors

- Reliable and reproductible sensitivity performances

- Small dispersion of the sensor specifications due to batch fabrication processes

- Linear output signal versus target gas concentration

- Very stable long term operation

- High mechanical resistance

- No field maintenance