- Home

- Companies

- 3T Analytik GmbH & Co. KG

- Products

- 3T-Analytik - Model QCM-D -qCell µOpt - ...

3T-Analytik - Model QCM-D -qCell µOpt -Microfluidic and Optical Module

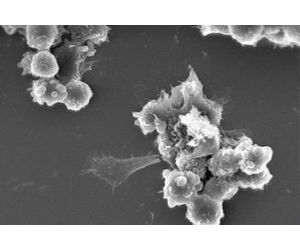

The qCell μOpto is the latest innovation to our QCM-D instruments. It is designed for combining 3T’s advanced QCM-D technology with up to 600X simultaneous microscopic observation of the sensor surface. Combining QCM-D with real time microscopy allows the user to evaluate frequency and damping with respect to sample surface coverage and morphology. Use this combination to analyze the sample surface coverage and get further insights to the sample’s mechanical properties and surface coupling. Applications include, but are not limited to, colloid attachment, bacterial adhesion, biofilm formation and cell adhesion and spreading.

The qCell μOpto can be operated separately or in conjunction with instruments of the qCell T family.

Combine the qCell μOpto with LiquiBox PT, for accurate temperature control and automatic fluid and sample control. The automation granted with the LiquiBox PT, enables excellent stability and reproducibility for long term unattended measurements. For transferring experimental protocols into a script, the qGraph software comprises the programming of temperature, flow rates, injection volume, sample channel, base line stability control, user defined equilibrium proceeding conditions and triggering of external devices.

Features of qCell μOpto series:

- QCM-D combined with Microscopy

- Compact design, compatible with most microscope stages

- Automated Pump Control

- Dissipation/Damping & Frequency Monitoring

- Optional Automated Control for up to 8 Independent Samples

- Peltier Driven Temperature Control

- User Friendly Software Interface

- Easy Handling

3T-analytik has developed quartz sensor instruments, the qCell-family, based on Quartz Crystal Microbalance (QCM) technology. The high sensitivity to mass and structural property variation enables QCM to be a powerful tool for gaining real time insights into molecular interactions, biofilms, liquid properties and even the analysis of blood. Quartz sensors are highly sensitive to the mass and the material properties of deposited molecular layers as well as of the wetting liquids at their surface.

As the QCM-D applications grow everyday, the technology brings users new experience and insights to their experiments. A crucial part of applying QCM-D is the interpretation of signals. It`s important to understand the correlation between frequency/damping and the interaction on the sensor surface. We present here some examples to help you learn the technology background in various applications.

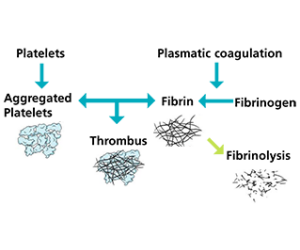

Coagulation of blood involves different processes, which can have different physical effects. In the primary hemostasis, platelets adhere to the damaged endothelium, to form a platelet plug. In secondary hemostasis, fibrinogen is polymerised to fibrin to reinforce the plug, which also converts the surrounding blood from a liquid to a gel like substance, i.e. the viscosity of the blood changes. Both processes, the adsorption of cells to a surface, as well as the change of the viscosity of a liquid, can be detected with QCM by measuring the change of frequency together with damping. Being a real time method, QCM is perfectly applicable for coagulation measurements. Different parts of the hemostatic process can be triggered by adding different coagulants to the blood sample.

In the past decade, the QCM has emerged as a powerful analytical tool, that is capable of detecting the response of living cells that adhere to the crystal surface. The amplitude of the acoustic shear wave drops exponentially with distance from the sensor surface. This is important for cell analysis with QCM, as the sensor will only be sensitive to the portion of the cell in the vicinity of the surface. The penetration depths δ of the acoustic wave is given by

δ=√(η_l/(?_l πf_0 ))

where ?_l is the density of the liquid and η_l is its dynamic viscosity. If one assumes the cell to have properties like water and the resonance frequency being f_0= 10MHz, the resulting penetration depth is δ= 179nm. The QCM sensor is thus sensitive to the interactions of the cell with the sensor surface and insensitive to changes in the inner portion of cells. The process of adhesion of cells to the substrate is vital for survival, differentiation and migration of many types of cells. By providing information about cell adhesion, QCM is a unique tool to obtain insight into the behavior of both healthy and infected cells. Mammalian cells will not be damaged during the measurement process, because the amplitude of the acoustic wave is too small to cause any damage. The second strength of QCM in cell analysis is the possibility to monitor the impact of environmental stimuli to the behavior of cells in real-time. Environmental stimuli range from cytotoxins, coagulants, growth factors, etc. to the presence of bacteria. Reactions of cells range from changes of adhesion, division, migration, to death and removal of cells. All of these reactions lead to changes in frequency and/or damping.

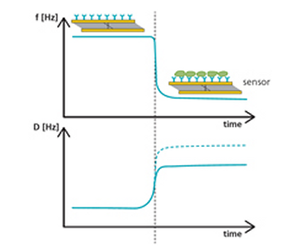

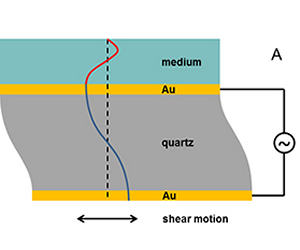

The measuring principle of quartz sensor technique is based on the precise oscillation of the quartz sensors at their resonant frequency when an alternating voltage is applied. Depositions at the surface or wetting of the surface result in a frequency shift and – depending on the material properties – additionally in a damping of the oscillation. Both, the frequency shift and the damping (dissipation) of the oscillation are captured with the qCell / qCell T instrument with high resolution and in real time.

3T-analytik has developed quartz sensor instruments, the qCell-family, based on Quartz Crystal Microbalance (QCM) technology. The high sensitivity to mass and structural property variation enables QCM to be a powerful tool for gaining real time insights into molecular interactions, biofilms, liquid properties and even the analysis of blood. Quartz sensors are highly sensitive to the mass and the material properties of deposited molecular layers as well as of the wetting liquids at their surface. Due to its sensitivity to mass, the technique is often referred to as Quartz Crystal Microbalance (QCM). The measuring principle of quartz sensor technique is based on the precise oscillation of the quartz sensors at their resonant frequency when an alternating voltage is applied. Depositions at the surface or wetting of the surface result in a frequency shift and – depending on the material properties – additionally in a damping of the oscillation. Both, the frequency shift and the damping (dissipation) of the oscillation are captured with the qCell / qCell T instrument with high resolution and in real time.

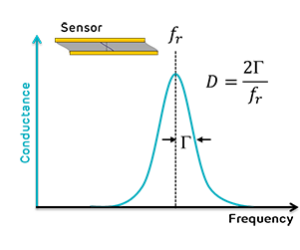

QCM is employed as transducer consisting of a piezoelectric AT-cut quartz crystal coated with two gold electrodes, one on each side. Upon application of an alternating voltage between the electrodes, the crystal will generate a mechanical shear wave, which is why the sensors are also referred to as Thickness Shear Mode Transducers. If the wavelength of the shear wave matches twice the thickness of the crystal, a standing wave is formed, which will propagate as an evanescent wave into the deposited layer on the upper sensor surface. The penetration depth of the wave is 179nm at 10MHz in water. The sensor is sensitive to mechanical properties of the deposited layers, such as density, thickness, viscosity and elasticity. Layer properties affect the resonance frequency fr as well as the damping parameter Γ, which is proportional to the energy dissipated in the layer. The relation between dissipation D and damping Γ is D = 2Γ/fr .

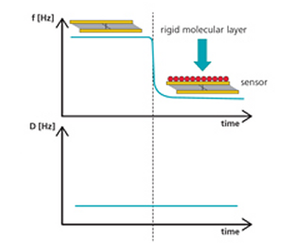

In QCM applications including layer thickness measurement of thermal metal deposition and self-assemble monolayer attaching, in which either rigid materials were used or layer thickness is at molecular level, the damping parameter varies in a tiny amount and is often negligible . Therefore the mass change per area can be directly related to the frequency shift ?fSauerbrey which is described in the Sauerbrey equation:

?fSauerbrey = -Cr · ?m

Here Cr is a constant relating to quartz thickness, density and the resonance frequency and surface area of the quartz sensor. The relation between frequency shift and mass change in Sauerbrey relation is simple and straightforward. However it is applied upon certain assumptions: the deposited layer is considered laterally homogeneous and thin; The layer is rigid and all stresses are proportional to strain; The QCM is working in vacuum. In reality it is often hard to satisfy when operation environment changes from air to liquid or the deposited layer is not viscoelastic. The frequency shift alone cannot provide sufficient information to surface changes. It is then necessary to take damping into consideration.

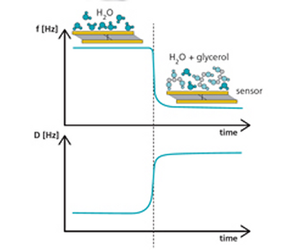

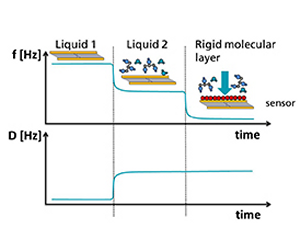

When the QCM sensor top surface is immersed in fluids, unlike in vacuum, the oscillation of the quartz is damped. This results in changes in frequency and more importantly the damping parameter Γ. Furthermore, the frequency and damping shift depend on the fluid’s properties. The figure shows an example of the influence of different fluids. When immersed in different pure Newtonian fluids (e.g. water and water-glycerol mixture in the figure), the fluid with higher viscosity and higher density will cause a decrease in frequency and an equal amplitude increase in damping. This is defined by Kanazawa:

ΔfKanazawa = -ΔΓKanazawa = -Cf √(ηl ?l )

Cf is a constant relating to quartz shear modulus, quartz density and resonance frequency. ηl is the dynamic viscosity of the fluid and ?l is the density of the fluid.

In this situation, the layer is completely determined by its density and its thickness. In this case, the two contributions above just add, which means Δf=ΔfSauerbrey+ΔfKanazawa and ΔΓ=ΔΓKanazawa.

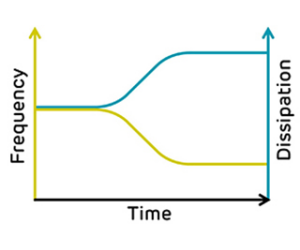

Viscoelastic Layer covered with liquid

The damping of oscillation is no longer negligible when the thickness of the deposited layer increases. The mass as well as elastic property of the material influence both frequency and damping. Unlike in Newtonian fluids, the frequency and damping shift vary in opposite direction but in different amplitude.