- Home

- Companies

- Kimre Inc.

- Products

- Kimre Accu-Pac - Model CDX-80 & CDX-150 ...

Kimre Accu-Pac - Model CDX-80 & CDX-150 -Mist Eliminators

Kimre mist eliminators are state of the art, durable, high efficiency and with cell design that will meet the most stringent mist removal specifications. Special features are included in the designs for Counterflon and Crossflon toners. Kimre mist eliminators provide ultra-Ion drift loss and are used in Cooling Toner, Evaporative Cooling, Turbine Intake Cooler, Scrubber and High Humidity Cooling systems.

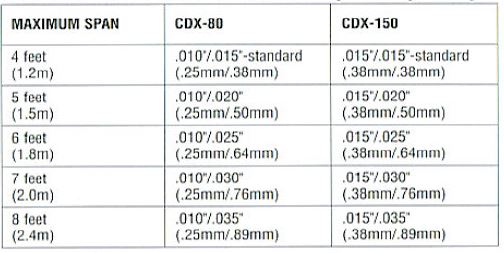

AccuPac DESIGNED MIST ELIMINATORS - Kimre mist eliiiiiiiatoi^s utilize a series of sinusoidal-shaped corrugations bonded to mating sinusoidal structural waves to foim closed cells that force the leaving airstream to make three distinct changes in direction. Hie drift droplets earned in the airstream. when forced to make die changes in direction in each cell, aeate centrifugal forces on the drift droplets, forcing them to be captured by ineitial impaction and direct interception. The high surface area of cellular eliminators and these unique design features, as well as those noted below, ensures state-of-the-art drift removal efficiency. Because tliis design utilizes stmctural waves between the corrugated cells, these drift eliminators can be manufactured to meet span requirements up to 8 ft. (2.4m). Tliis improvement in strength and span capabilities reduces the net blockage of air due to additional support beams. Additionally, these mist eliminators can be field cut for a tight fit around columns and other structure without sacrificing any sttuctural integrity.

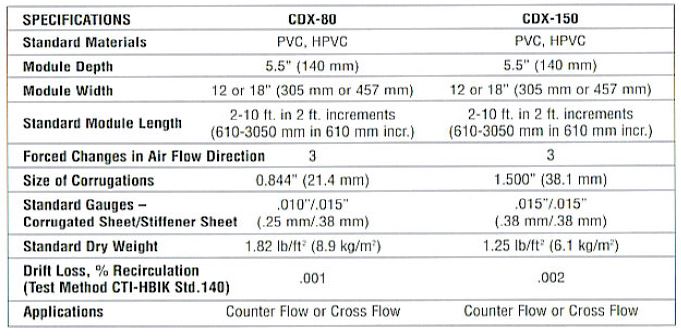

CDX-150 AND CDX-80 - Designed in two different densities, these cellular drift eliminators meet the needs of all tower designs. The CDX-150 is designed with a cell dimension of 1.50" (38mm) to provide maximum perfoimance at minimum pressure drop and cost. Tliis is our most often purchased product. The CDX-80 is designed to meet the most stringent specifications where very low drift levels are required. The drift removal efficiency of tliis product is imequaled in tlie iiidiistiy. Tlie CDX-150 and the C`DX-80 aie designed for applications in either cioss flow or counter flow cooling tower* SPECIAL FEATl"RES NESTING: Our CDX-80 and CDX-150 aie designed so tliey nest or interlock with the module next to them, eliminating interfaces between modules. This important feature eliminates a possible b)pass of the aii` that can occur when modules aie not tightly sealed at the module-to-module interface. In a flat sheet design any small gaps between the flat sheets will cause an* to bypass the eliminator, taking the patli of less resistance and canning chift droplets with it.

DRAINAGE CHANNELS: Our unique design for cross flow applications allows captiued drift droplets to be removed as a film of water through drainage channels. Once drift droplets are captiued on the side walls of the eliminator, they form a film of water that flows down die wall \ia gravity to the drainage channels and then out the bottom of the eliminator, reducing the opportunity for rein-trainment Other manufacturers` designs force the captiued water to the face of the eliminator where it trickles down the edge, allowing more opportiuiities for reintrainment as drift droplets. Drainage chamiels aie a unique AccuPac design tliat can greatly improve the drift removal efficiency of your cooling tower.