- Home

- Companies

- Ekogrid Oy

- Products

- Ekogrid - Mixing Technology for Soil ...

Ekogrid - Mixing Technology for Soil and Groundwater Remediation

EKOGRID™ technology can be used in conjunction with other remediation methods when treating contaminated soils and groundwater. The most frequently used combinations to date include coupling EKOGRID with pump & treat systems and with other additive based enhanced bioremediation solutions. In standard remediation (induced electrolysis) mode, EKOGRID™ pulses are equally timed in both directions between the electrode rows. In addition to inducing electrolysis the low voltage current makes the charged contents of the pore water move back and forward resulting in the electrokinetic mixing effects at the soil particle level but no bulk movement in the direction of any electrode.

In transfer mode the EKOGRID™ control unit generates longer pulse in one direction than in the other direction. The uneven pulse pattern results in the movement of soil cations, other soluble elements and water through the soil and groundwater in a direction determined by the transfer pulse.

The transfer mode set up can be used in a wide variety of setups. It is typically used in conjunction with the standard EKOGRID (even pulse) set up on remediation projects. The control unit will be switched to transfer mode when nutrient additives are applied in order to spread the nutrients through the soil. Soil nutrient content is often the limiting factor with enhanced bioremediation. The control unit will then be switched back to an even pulse pattern to continue the electrokinetic enhance bioremediation processes.

The transfer mode can also be used purely to increase the effectiveness of other remediation approaches:

- Pump and Treat: Cathodes are installed in the pumping wells and anodes to areas where the contaminants are located. The transfer pulse is set to enhance movement towards the cathodes. Flow of water is enhanced significantly and the gradient towards the well is increased.

- Distributing additives: When adding remediation additives, whether they be nutrients, enzymes, surfactants or other chemicals, getting the additives to distribute through the area of contaminated land can be challenging. The utilization of the EKOGRID system in transfer mode can vastly speed up the spread of additives. Additives can be applied by a drip-line type of irrigation system between the electrode rows or perforated tubular electrodes can be used and the additives injected into the soil directly at the electrodes.

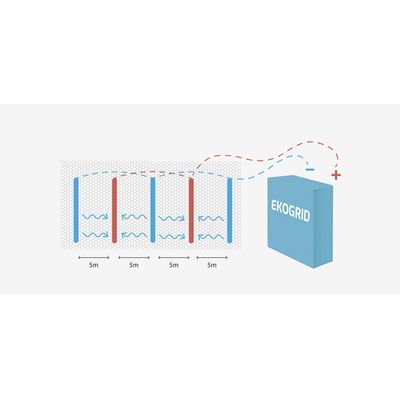

The diagram below illustrates the operation of a transfer pulse with the longer pulse set from blue electrodes to red electrodes, thus creating a push of water and additives towards the red electrodes.

- EKOGRID™ control unit,

- Electrical connection or alternative energy source,

- Electrodes installed to the depth of contamination to be treated,

- Cables and connections,

- Software,

- Know-how of the EKOGRID™ experts,

- Combination with other solutions which is typically optimized by local partners in each market as they have the knowledge if the local offering.

EKOGRID is an electrokinetic method that utilizes natural well-known phenomena and reactions:

- Electro-osmosis, electrophoresis and electromigration,

- Electrochemical redox reactions (e.g. electrolysis),

- Bioremediation processes, increased microbial activity.

The core of this unique system:

- Optimized pulsed voltage output,

- Frequently changing polarity of the output:

- This makes the charged contents of the pore water move quickly back and forth (short electro-osmotic pulses) so that freshly formed free radicals and oxygen that promote the oxidization of compounds emerge.

- The system uses the capacitive nature of the matrix (soil), thus enabling it to work at a very low output voltage.

- Reactions will occur at the surface of each soil particle and evenly spread throughout the whole matrix and precisely where the pollution is. The finer the soil grain size, the more effectively the system operates due to faster and more complete remediation.

EKOGRIDTM patented products and technologies are cost-effective, simple to install, and safe to use both for the operators and the environment.

With the correct settings made in the commissioning phase, our system utilizes the capacitive nature of the soil matrix. Reactions will occur at the surface of each soil particle, precisely where the pollution is and everywhere between the electrodes -not just at the installed electrodes. As a result, no energy will be wasted and the system will consume extremely low levels of energy. The effect can be quickly seen in the form of reduced pollutant concentrations in the soil and groundwater as well as stabilized ORP and dissolved oxygen levels.

- Continuous and sustained degradation of target compounds

- Easy to install with relatively low related costs

- Works on soil, groundwater and sediments, and especially well in low-permeable soils such as clays, silts and fine sands

- Enhances in situ degradation of broad range of organic contaminants

- Intelligent system based on natural phenomena,

- No secondary pollution from noise, gas or particle pollution,

- Low power consumption and very little resources needed for operations and maintenance,

- No hazardous chemicals needed,

- No harm to fauna or wildlife,

- Alternative/renewable energy source-compatible,

- Simple logistics and work safety: in situ treatment requires no transport and thus can be carried out discreetly. There is no need for personnel to be on site except during installation, dismantling, and measurement sampling.

- Enhances bioremediation

- Groundwater aquifers are treated simultaneously with soil

The technology has proven to work on a substantially wide range of organic pollutants in the ground, ground water and bottom sediments, including:

- Aliphatic hydrocarbons (gasoline, petrol, diesel, heavy oil)

- Benzene, toluene, ethylbenzene, xylenes (BTEX compounds), MTBE, ETBE and TBA

- Polycyclic aromatic hydrocarbons (PAHs)

- Chlorophenols

- Chloroethenes (TeCE, TCE, DCEs and MCE)