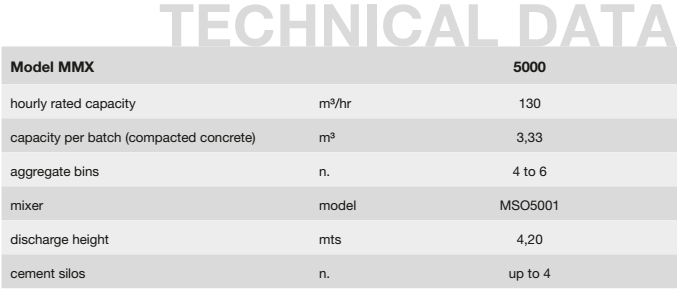

Simem - Model MMX -Mobile Concrete Mixing Plant

MMX stands for Mobile Mixing eXcellence, and represents in Roman Numerals the year 2010, which is the year SIMEM has officially launched the state of the art of super mobile batching plants, worldwide! Two patents for industrial property referring to the moving mechanism of the mixer and chassis hood-scales were acquired by SIMEM in 2009, clearly establishing the innovation in the MMX. Thanks to these inventions, the concrete batchingand mixing plants can ensure an hourly output capacity of 130 cubic meters ofhigh quality concrete, and have a structure that allows for easy transport with generic vehicles

After over 45 years of experience in design and production of batching and mixing plants, the new SIMEM MMX mobile plant evolves the concept of transportability and is an improvement to the concept of wheels: streamlining the plants overall dimensions to allow transport with generic vehicles, which do not require special permits, the new SIMEM MMX mobile allows easy and economic transport.

- High-quality twin shaft mixer featuring construction strength, high productivity, high quality of wear parts with the lowest maintenance cost per cubic meter of concrete produced.

- Hydro-dynamic engineering contributes to mixing paddles and arms reduce wear also providing an optimized mixing result.

- Heavy-duty and long-lived mixer suitable for WET and SCC concrete, RCC concrete, MASS concrete and applications for treatment of industrial solid waste

The aggregate module is made with a modular concept and can therefore be made expandable by adding additional modules as a priority to expand the number of hoppers available and therefore the types of aggregates.

Regarding the storage capacity of aggregates, you can switch easily from the basic con?guration of 80 cubic meters to the con?guration of 180 cubic meters.

Simem@tic is an easy to use automation with unbeatable accuracy and flexibility for uninterrupted operation.

- Familiar Windows operating environment with SQL database

- Flexible reporting and backup functionality

- Real time flow correction for each material

- PC/PLC based

No civil works are required as the bulkheads below the aggregate module have a double function to support the aggregate module due to large areas of support: thus, it is possible to use the module without the need of civil works. Moreover, it act as restraints for the items loading ramp for aggregate feeding. Access to the mixer is made easy thanks to a patented system of rails and hydraulics that moves the weighing devices.