Simem products

Plant

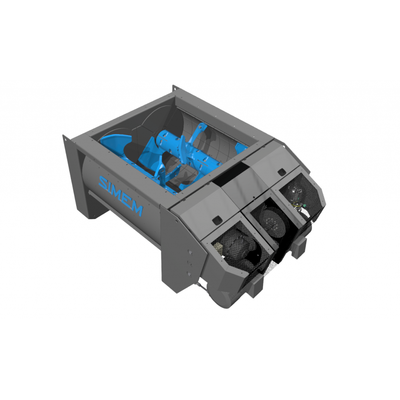

Simem - Model MMX - Mobile Concrete Mixing Plant

MMX stands for Mobile Mixing eXcellence, and represents in Roman Numerals the year 2010, which is the year SIMEM has officially launched the state of the art of super mobile batching plants, worldwide! Two patents for industrial property referring to the moving mechanism of the mixer and chassis hood-scales were acquired by SIMEM in 2009, clearly establishing the innovation in the MMX. Thanks to these inventions, the concrete batchingand mixing plants can ensure an hourly output capacity of 130 cubic meters ofhigh quality concrete, and have a structure that allows for easy transport with generic vehicles

Simem - Model Eagle - Semi Mobile Batching Plant for Road Construction

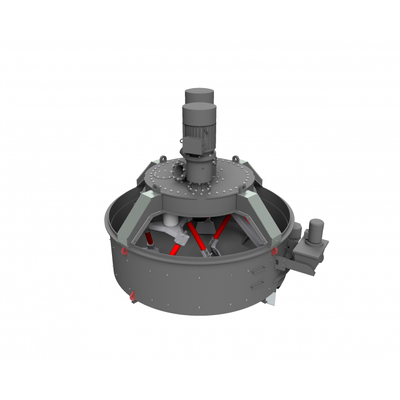

Simem - Model Bison Dry - Dry Concrete Batching Plant

FEATURES - Hourly Rated Capacity ton/h : Up to 45-95 m3/hr (depending on aggregates units). Aggregate Hoppers n : 1 to 4. Powder Dosing System n : 1. Numbers of cement silos : up to 4. Discharge Height m : 4,2.