- Home

- Companies

- Wagner Magnete GmbH & Co. KG

- Products

- Model 0434 - Stainless Steel Separator

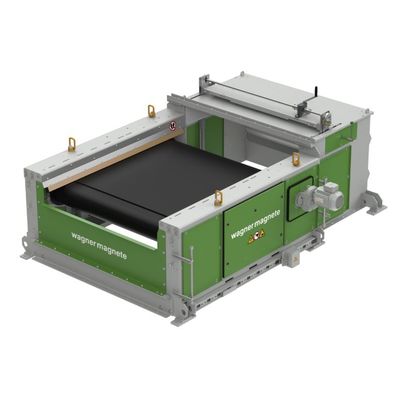

Model 0434 -Stainless Steel Separator

The stainless steel separator of the 0434 series is based on the chassis of our eddy current separators. The machine can be combined with attached magnetic drum separators, upstream vibratory feeders or downstream non-ferrous separators. Dust-protected versions can be realised without any problems. The separate control system with state-of-the-art components can communicate with a higher-level system control via Profibus or Profinet.

HOW DO STAINLESS STEEL SEPARATORS WORK?

Magnetic separator - Group: Stainless steel separators

Magnet design: Neodymium magnet

Active system: Holding on

Grain size: 0 - 50 mm, 50 - 100 mm

Conveyed goods: Automobile shredder, Electronic waste, Rock, Foundry sand, Glass, Wood, Bulky waste

Separation target: High product purity

Areas of application: Waste wood, Waste paper and glass, E-scrap, Commercial waste, Plastics, Building rubble, Scrap processing, Bulky waste