Wagner Magnete GmbH & Co. KG products

Magnetic Separators - Stainless Steel Separator

Stainless Steel Separator

The centrepiece of all WAGNER Stainless Steel Separator Pulley 0431NV is the innovative neodymium magnetic belt roller with a diameter of 400 mm. The strongest magnetic material currently available is fitted into the magnetic carriers using special devices in such a way that the magnetic field on the roller surface is extremely strong and at the same time the greatest possible depth effect is achieved. Many stainless steels that are only weakly magnetisable and therefore could not previously be deposited are held by the roll. Due to the large spatial expansion of the magnetic field, even unfavourably shaped stainless steel parts are optimally magnetised.

Stainless Steel Separator

Our basic machine 0432NV is limited to what is really necessary and can therefore be easily retrofitted as a stand-alone unit in existing systems. Our strong 0431NV belt roller is combined with an extremely thin yet high-strength, positively driven PU conveyor belt. It is driven by a three-phase motor with integrated frequency converter.

Stainless Steel Separator

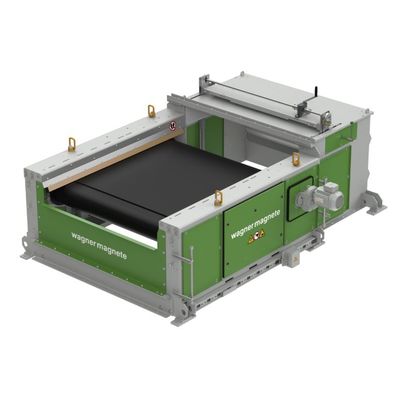

The stainless steel separator of the 0434 series is based on the chassis of our eddy current separators. The machine can be combined with attached magnetic drum separators, upstream vibratory feeders or downstream non-ferrous separators. Dust-protected versions can be realised without any problems. The separate control system with state-of-the-art components can communicate with a higher-level system control via Profibus or Profinet.

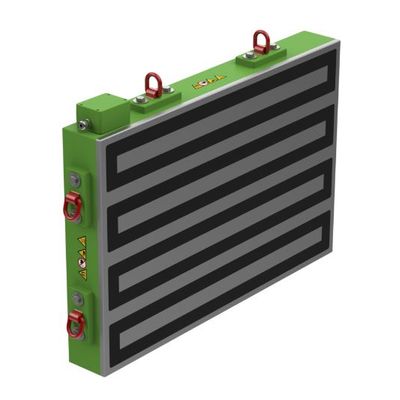

Clamping Magnets

Electro Magnet Chuck

Radial pole spacing is particularly suitable for centric clamping of workpieces such as flanges, rings or similar rotationally symmetrical components. The radial pole arrangement has particular advantages if you want to clamp individual, ring-shaped or round workpieces centrally - e.g. for cylindrical grinding, turning and similar applications. A major advantage of the radial pole arrangement is the possibility of releasing the workpieces via pole shoes. The workpiece can therefore be finished on three sides in a single clamping operation with optimum shape and position tolerances . The pole shoes can be moved in the T-slots and thus ideally adapted to the existing workpiece diameter. The pole plate can be customised to your requirements at any time. Possible options include additional threaded holes, T-slots, profiles and much more.

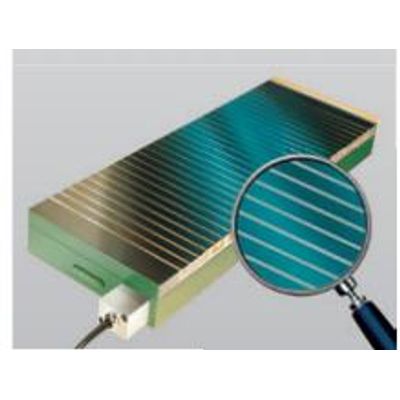

Grinding Magnet with Transversal Pole Spacing

The internal polarity reversal of this magnetic system corresponds precisely to the distribution of the pole on the clamping surface, which means the adhesive force is uniformly distributed over the entire clamping surface. This pole spacing also allows you to clamp workpieces to the longitudinal sides of the pole plates. Application: universal grinding magnet.

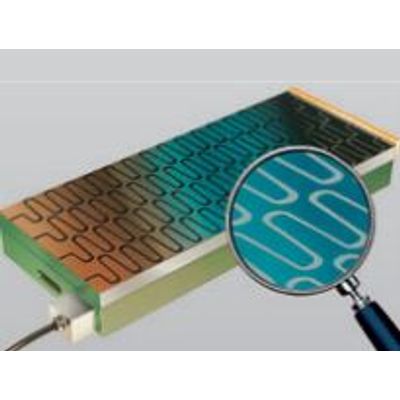

Sinusodial Pole Spacing Magnet for Grinding Applications

This specifi c type of pole spacing offers you a symmetrical distribution of north and south poles over the entire clamping surface – in both longitudinal and transverse directions. This arrangement means the clamping plate has a particularly even adhesive force over the entire pole face. Application: grinding, milling