- Home

- Companies

- Wagner Magnete GmbH & Co. KG

- Products

- Model 121 - Electro Magnet Chuck

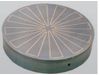

Model 121 -Electro Magnet Chuck

Radial pole spacing is particularly suitable for centric clamping of workpieces such as flanges, rings or similar rotationally symmetrical components. The radial pole arrangement has particular advantages if you want to clamp individual, ring-shaped or round workpieces centrally - e.g. for cylindrical grinding, turning and similar applications. A major advantage of the radial pole arrangement is the possibility of releasing the workpieces via pole shoes. The workpiece can therefore be finished on three sides in a single clamping operation with optimum shape and position tolerances . The pole shoes can be moved in the T-slots and thus ideally adapted to the existing workpiece diameter. The pole plate can be customised to your requirements at any time. Possible options include additional threaded holes, T-slots, profiles and much more.

- a solid steel base

- a copper winding

- a pole plate

A decisive quality feature of WAGNER clamping systems is the optimum balance between electrical power consumption and achievable magnetic force.

Einsatzgebiete: Turning processing, Polishing/Deburring, Grinding processing

Pole pitch: Radial pole pitch

Pole distance: depending on the size

Processing type: Multi-page processing

Control system: Pole reversal control unit

Holding force control: Multi-stage adhesive forces

Magnet design: Electro-magnet

Design: Round

Areas of application: Machine tools, Wind turbines

Ausführungsoptionen: Pole-Plates, Air Purge Holes, Pass-through Holes, Inserts, Adaptation Flange, Threaded holes, Customized Solution, T-Grooves, Pole-Extensions, Current-Transmission via Slip-Ring-Unit and Carbon-Brushes, Centering Inserts