- Home

- Companies

- Chromasens GmbH

- Products

- Model allPIXA neo - Cmos Line Scan ...

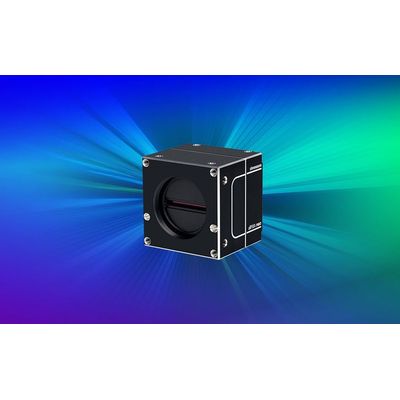

Model allPIXA neo -Cmos Line Scan Camera

allPIXA neo. Fast and versatile power cube. Compact design with high performance multispectral sensor. The new allPIXA neo CMOS line scan camera delivers highest performance in mono, RGB and NIR with 4k / 6k resolution. Equipped with 10 GigE and CoaXPress interfaces it is the best solution for all high-speed and web inspection tasks. With its small size, it enables simple and scalable integration in small installation spaces. This industrial line scan camera family sets new standards for inspection. It is based on quadlinear CMOS sensors and opens up possibilities in sorting by combining multispectral RGB + NIR imaging technology.

Multispectral line scan sensors with excellent signal to noise ratio allows to accurately capture images in high quality. Small pixel sizes of 5 µm and 7 µm enable shorter sensor lengths, allowing a more compact design and the use of standardised M42 and F-mount lenses. The camera delivers best results at high speeds thanks to the high sensitivity of the sensor.

The camera series provides the industrial interface standards 10 GigE and CoaXPress with cable lengths up to 100 m. The interfaces enable Power over Ethernet (PoE) and Power over CoaXPress (PoC).

The 10 GigE interface enables easy and economical integration with line rates up to 90 kHz in color and 270 kHz in mono. CoaXPress interfaces reach maximum speed with line rates up to 105 kHz in color and 300 kHz in mono.

For easy setup, the camera comes with intuitive Chromasens GCT software compatible with Linux/Windows. The included SDK enables fast implementation in complex industrial machine architecture via GenICam standard.

The allPIXA neo line scan camera series exceeds the requirements of demanding applications, such as material sorting, web inspection and general machine vision tasks.

The additional NIR channel available provides useful information that is not visible in the RGB wavelength spectrum and adds valuable information beyond the RGB images. As a result, the inspection identifies an even greater number of defects on the objects examined or foreign parts, for example in food sorting.

- High-speed Web Inspection

- Logistics

- Pharma

- Food Inspection

- Battery Inspection

- Sorting

- Electronics

- Print and Packaging