- Home

- Companies

- CK International Ltd.

- Products

- Model CK-TR121XL - Twin Ram Baler

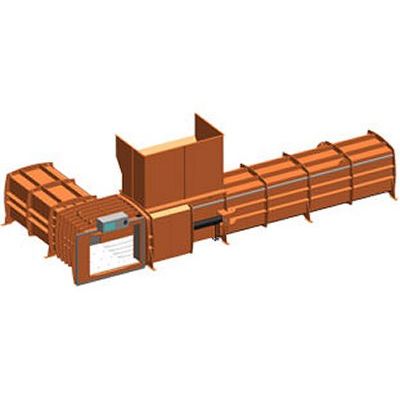

Model CK-TR121XL -Twin Ram Baler

The CK-TR121XL is a fully automatic twin ram / two ram baler suitable for baling a wide variety of materials. Depending on material and feeding method, throughputs of over 4 tonnes per hour can be achieved. A range of bale tying methods is available to suit various customer applications.

- Fully automatic cycle

- Choice of tying options as detailed below

- Shear blade on top of press plate, allows continuous material feeding.

- 22kW motor for short cycle time

- Full bale eject for fast bale discharge

- Magic eye start-up so operator can continuously feed material

- Enormous feed opening for ease of loading

- Large bale saves time tying bale, reduces the amount of wire used and saves time loading containers

- Robust heavy duty construction for long life

- Replaceable Hardox wear plates throughout machine

- CE marked

- 2 year warranty on purchased machines

- 5 year fixed cost all inclusive rental option

- H*xWxL (m): 1.5 x 4.2 x 9.2

- Feed opening (mm): 2250x1060

- Weight (approx) (kg): 16000

- Cycle Time (sec): 38

- Compaction force(T): 80

- Power Supply (V): 415 (three phase)

* Height excluding hopper

- HxWxL* (mm): 1100x1100x1400

- Bale Weight : up to 1 tonne

- Bale length variable between 1200-1500mm

- Optimum bale size for containerisation and reduced handling

- Bale size & weight depends on material baled

A range of tying options is available including wire and polyester strapping to suit the customer`s particular application.

Wire tying is particularly suitable for processing cardboard, plastic and PET and is the traditional method used.

Alternatively bales can be tied using polyester strapping. This is especially suitable for RDF or SRF, where the banding material is incinerated along with the waste.

Depending on the outlet for bales polyester strapping can also be used for other materials as a lower cost option.