- Home

- Companies

- Messinger Engineering

- Products

- Model CT01 - Ceramic Membrane Test ...

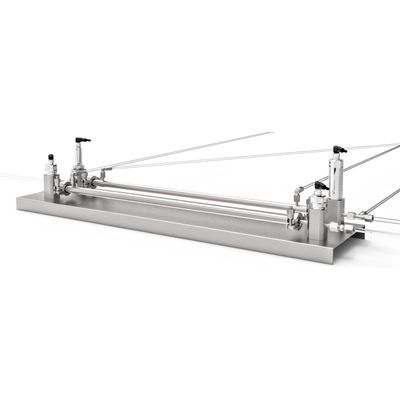

Model CT01 -Ceramic Membrane Test System

Laboratory plant for membrane filtration / membrane technology. Benchtop system with a single ceramic tubular membrane. The properties of the ceramic, such as high overflow, high temperatures, pH stability, etc., can be fully utilised thanks to the solid, high-quality design and the installed components.

The CT-1 test system for individual ceramic tubular membranes was developed in response to urgent requirements in the industry. Customers seek a user-friendly, easy-to-understand ceramic membrane system for their initial trials. However, the system must also provide reliable results that can be used for scaling up. It must also be possible to test the ceramic single membrane used in the entire possible range of operating parameters, such as high overflow (5-7 m/s), high temperatures (90°C), extreme pH ranges, etc.

Our new ceramic membrane test system CM-1 fulfils all these requirements and is also very compact, mobile and of extremely good quality.

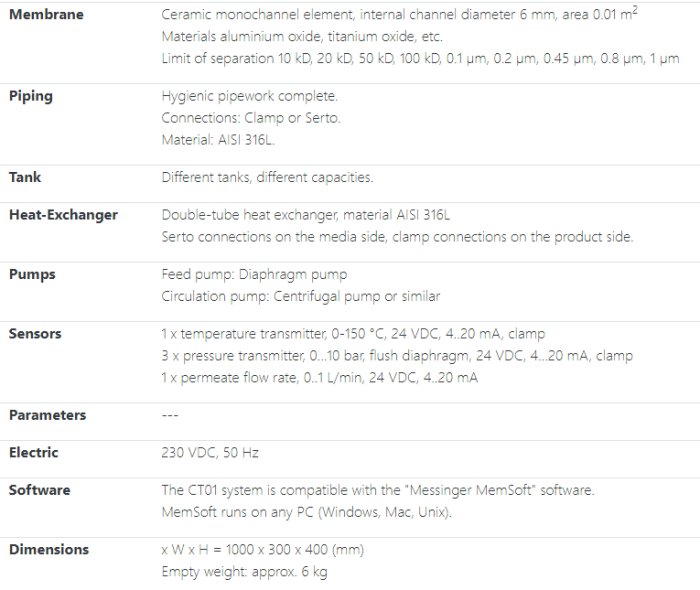

CT-1 precisely controls and maintains constant experimental parameters such as temperature, pressure, flow rate and calculated parameters such as concentration factors, pressure drop, transmembrane pressure etc.

High-precision sensors are installed that ensure accurate and reliable measurements.

Open-source software allows for continuous refinement, expansion, and integration to meet future needs. This software adapts to your requirements, rather than forcing you to adapt to it.

The accuracy of the system is astonishing. The system allows an enormously good scaling-up capability from laboratory to industrial scale. An overview of processes with ceramic membranes in the food sector: → Processes

Data acquisition, evaluation, interpretation and fully automated reporting with easy-to-understand graphics make it easier to recognise correlations.

The pipework system is designed in accordance with ASME BPE recommendations. The consistent use of standardised fittings ensures consistent modularity, so that the basic system can be expanded into a mini-plant of any complexity, an interconnected system with additional process engineering equipment and analysers.

Cleaning and maintenance: Simple and effective cleaning and maintenance procedures are implemented to avoid contamination and ensure the reliability of the system.

The test system CT-1 is structured as a versatile construction kit, characterized by its modular design comprising various building blocks. These components are clever designed to accommodate a diverse array of testing requirements tailored to specific inquiries. Through the addition of these modular elements, the test system allows examinations across all domains.