Model CUP-FK -Multistage Pump

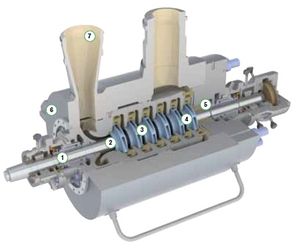

ClydeUnion Pumps has vast experience, over 70 years, of supplying large high speed multistage pumps. Our extensive engineering, manufacturing and operational experience has been incorporated in the design of the CUP-FK, a radially split, barrel case, multistage diffuser pump designed for high pressure, high temperature and high speed applications. A world leading product with features such as optimum hydraulic design, sustainable efficiency, full cartridge withdrawal, and the inherent ability to withstand thermal shock, the CUP-FK range pump offers reliable operation and low through life cost of ownership. The CUP-FK range has been designed to produce an advanced pump with reduced whole life costs. All the pump internals can be withdrawn quickly without disturbing pump alignment or pipework. This helps in saving time and making maintenance straightforward.

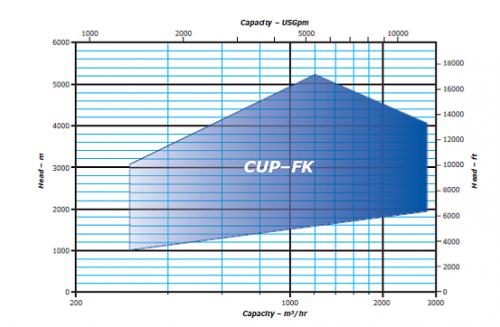

- Capacity: up to 2,800 m3/hr / 12,300 gpm

- Delivery head: up to 5000 m / 16,400 feet

- Temperature: up to 250 oC / 480 oF

- Speeds: up to 7,000 rpm

- Flange drilling: BS or ANSI

- Supercritical power plants

- Subcritical power plants

- Combined cycle power plants

- Cogeneration plants

- Industrial / refinery boiler feed

- Mechanically stiff shaft

- Large shaft-to-impeller diameter proportions. Short span between bearings. High critical speeds and low static deflection

- Optimum npsh performance

- Optimised by computational fluid dynamics. First stage impeller with inlet designed specifically for improved cavitation erosion providing extended life

- Optimised hydraulic performance

- Proven range. Precision cast components, repeatable performance and advanced manufacturing techniques

- Replaceable wearing parts

- Available for ease of maintenance. Casing wear rings material and geometry is selected for anti-galling properties

- Hydraulic thrust balance

- Balance drum removes the requirement for axial alignment. Extended pump performance with ability to handle transients and flow changes without wear

- Centreline mounting

- Reduced effect of thermal growth at elevated process temperatures. Maintains pump to driver alignment at all operating temperatures. High strength fabricated steel baseplate accommodates all static and dynamic loads and reduces noise transmission. Capable of supporting pumpsets grout free

- Connection options

- Flanged branch. Welded branch. Interstage tapping. Orientation to suit station pipework. Kicker stage connection