Model CUP-FT/FK -Multistage Pump

ClydeUnion Pumps has been designing and manufacturing multistage throughbolt and boiler feed pumps for nearly 100 years. The ClydeUnion Pumps CUP-FT/FK (2 Pole) is a world class product range designed for boiler feed applications, meeting the demands of modern thermal, combined cycle and solar power plants. Our extensive engineering, manufacturing and operational experience has been incorporated in the design of the 2 pole diffuser pump CUP-FT/ FK (2 Pole). A radially split case diffuser type pump with options for throughbolt (FT) or barrel case (FK), designed for low, intermediate and high pressure and temperature applications. A world leading product, with features such as optimum hydraulic design, sustainable efficiency, and the inherent ability to withstand thermal shock, the CUP-FT/FK (2 Pole) range pump offers reliable operation and low through life cost of ownership.

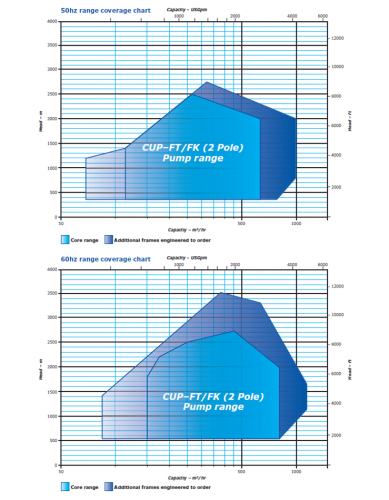

- Capacity: up to 1,100 m3/hr / 4,840 gpm

- Delivery head: up to 2,500 m / 8,200 feet

- Temperature: up to 180 oC / 350 oF

- Speeds: up to 3,600 rpm

- Flange drilling: BS or ANSI

- Boiler feed

- Reverse osmosis

- Mine dewatering

- Descaling

- Mechanically stiff shaft

- Large shaft-to-impeller diameter proportions. Optimal span between bearings. High critical speeds and low static deflection

- Optimum NPSH performance

- Optimised by Computational Fluid Dynamics. First stage impeller with improved suction performance. Single and double entry available

- Optimised hydraulic performance

- Proven range. Precision cast components, repeatable performance

- Replaceable wearing parts

- Available for ease of maintenance. Casing wear rings material and geometry is selected for optimum efficiency and rotor stiffness

- Oil pump

- Shaft driven lubrication oil pump when required

- Centreline mounting

- Reduces the effect of thermal growth at elevated process temperatures. Maintains pump to driver alignment at all operating temperatures. High strength fabricated steel baseplate accommodates all static and dynamic loads and reduces noise transmission. Capable of supporting pumpsets grout free

- 360° bearing support

- Optimum rotor alignment and support. Reduced vibration levels. Maximum component life

- Hydrodynamic bearings (Journal & tilting pad thrust)

- Capable of higher load operation. Generously rated hydrodynamic double-acting thrust. Force-fed or self-contained options available. Optimum rotor stability. Infinite life dependant on oil cleanliness. A balance disk option is available that does not require a hydrodynamic thrust bearing

- Mechanical seal

- Cartridge style, no seal setting. Reduced capital cost. Long seal lives achievable. Plan 23 or cooled seat options available