Model GTO 12x30 -Coolers for Oil Cake

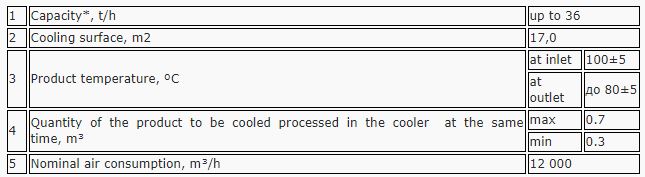

One of the significant goal of the fat-and-oil production is an increase of oil extraction grade. The methods of the iterative pressing or extraction are used for this purpose. However, this is a place where the producers are facing the problem – how to cool the seed cake? This is because the seed cake after oil pressing, except of having high fat content, is of high temperature (≈100-120ºÐ¡), that making the further extraction process dangerous through the possible explosion. Use of high effective GTO 12×30 cooler which is specially developed by the ICK Group’s specialists for seed cake cooling before further extraction is an answer to question.

Seed cake, so called “shell”, goes from the scraper conveyer by gravity through the longitudinal opening in cover 1 into the cooler where it is uniformly distributed along the surface.

Then the seed cake moving along the inclined surfaces of the panels 2 is cooled by the air flow which after that is withdrawn through air duct into cyclone and ventilator. The cooler design allows for regulation of the product movement speed and correction of its temperature respectively. The movable panels 2 which can be installed at various angles are used for this purpose. The equipment is easy to operate. The removable panels 3, which can be used, when required, for air flow improvement, are provided for repair of the conveyer and inner components of the cooler.

GTO 12×30 Cooler can operate continuously, thereby the special operator for cooler maintenance is not required.