CETCO

Most popular related searches

drinking water treatment chemicals

water treatment chemicals

oil-water separator

drinking water treatment

fouling

chelating agent

recovery well

air stripper

pump system

well water

LBA cleans casings, screens, and all other components of the well that are affected by bio-fouling or iron bacteria.

- LBA acts as a chelating agent, allowing more dissolved minerals to be pumped to waste, therefore preventing re-depositing of the minerals

- LBA has the ability to penetrate and disperse debris layers

- LBA is also used to debris fouling of environmental monitoring and recovery wells, oil/water separators, air strippers, and other types of equipment used in groundwater remediation

- LBA is non-corrosive and nontoxic

- Test well pH before starting treatment. Disconnect distribution system.

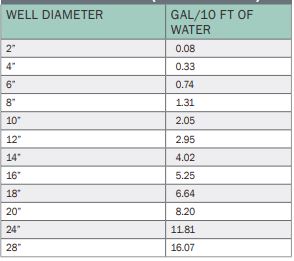

- Calculate quantity of LBA by using the Dosage Table. Normal dosage is 5-7% solution. If gravel pack is present, the volume of water in it should be accounted for as part of the total well volume (typical porosity of gravel pack is 30-40%).

- Add LBA directly into the well through the casing. Agitate the well for 12-48 hours by surging, jetting, or circulating the water. Compressed air may be used to agitate the well.

- Upon completing agitation, DPA can be added to the well if mineral encrustation is present.

- Pump the well until water is clean and free of acid to within 0.5 units of original pH. Reinstall pumping equipment.

- Chlorinate the well with a shock treatment of sodium hypochlorite at 500 to 1,000 ppm. Pump the well until clear of chlorine.

- 5 gallon pail, 27 or 28 per pallet, 15 gallon pail, 8 per pallet, o r 55 gallon drum, 4 per pallet. All pallets are plastic-wrapped.