- Home

- Companies

- Fronius International GmbH

- Products

- Model TransCut - Plasma Cutting System

Model TransCut -Plasma Cutting System

In the past there have been a number of drawbacks associated with plasma cutting. Not least, conventional cutting processes suffer from limited mobility due to the fact that they require a supply of compressed air. The large proportion of nitrogen in the plasma jet, moreover, encouraged chemical reactions at the heated cutting surfaces and the workpiece surfaces, which could lead to the formation of pores in the event of any subsequent welding. As an innovative plasma cutting process that requires no compressed air, TransCut avoids the accompanying symptoms mentioned and also allows operation that produces fewer pollutants.

Plasma cutting is one of the thermal cutting processes. The plasma - an extremely energy-rich and electrically conductive gas flow - melts the workpiece locally. The gas flow drives the molten material out of the kerf. Unlike conventional plasma cutting processes, TransCut gets by with a small quantity of liquid instead of a costly compressed air supply or a heavy compressor requiring a large amount of space and energy. The liquid serves firstly as the basis of an extremely high-energy plasma jet, and on the other hand it makes the cutting device totally independent from the compressed air supply.

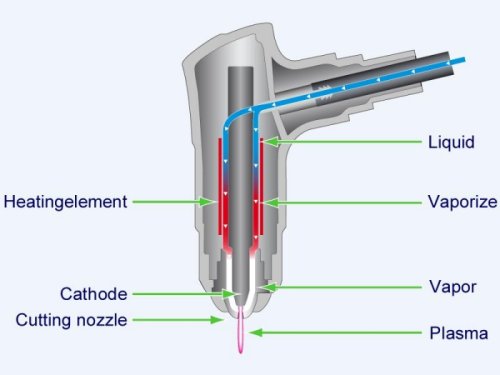

In the cutting torch, the liquid cutting medium evaporates as it flows past an electric heating element. At the same time, the in-flowing liquid raises the negative cathode of the positive cutting nozzle. A so-called pilot light arc ignites, and the cutting medium, which is now gaseous, is partially ionised. Even before the cutting torch gets close to the workpiece, a plasma is ignited, and as a result it is far easier to apply the plasma cutting torch when cutting begins.

As the cutting torch comes closer to the surface of the workpiece, the cutting jet focuses the cutting jet on the workpiece, which likewise has positive polarity. The process of switching over automatically from the pilot arc to the actual arc ensures that the work routine is harmonious.

The TransCut cutting device consists of a power source and a plasma cutting torch which is connected to the power source via a hose pack. The recently launched cutting device is light and compact as well as suitable for building sites and has an integrated supply tank for the cutting medium. In comparison with a gaseous cutting medium, the liquid is of high density. Just a small number of millimetres per minute are therefore sufficient, and as a result – depending on conditions on the ground – the supply will last for up to a month, A 230 V socket or a generator suffice as a power supply. The integrated power source works on the inverter principle, and ensures stable operation. There is no need for a supply of compressed air or gas.

The power source has an integral pump which conveys the liquid cutting medium from the tank to the plasma cutting torch. The cutting medium also serves to cool the cutting torch. As soon as the cutting torch has reached a specific temperature, much of the cutting medium evaporates due to the heat lost. This type of cooling is known as regenerative cooling since the lost heat is utilised again. At the end of the rapid warming-up phase, the electric heating element`s only remaining function is to support the process of evaporation. A complex system of regulation maintains an equilibrium in managing the heat.

TransCut is ideal for use as a mobile installation on construction sites. This procedure is suitable for all kinds of different industries including, for instance, air conditioning and ventilation systems, assembly companies, industrial plant and pipework, maintenance and repair as well as vehicle bodywork and panel beating. The TransCut cutting device cuts steel and chrome/nickel as well as aluminium, is generator-compatible, and enables high-quality cuts to be made in sheet metal of up to 6 mm thickness and separation cuts up to 10 mm.

A water-based cutting process means that intensive contact between the heated workpiece and the surrounding air, which does occur in procedures based on compressed air, is avoided. As a result, nitrogen enrichment of the cut surfaces as well as harmful oxidation of the workpiece surface are effectively prevented. In the event that welding is carried out later, the danger of pore formation is significantly reduced. In addition to the benefits listed above, the quantity of particularly harmful exhaust gases is also reduced. The emissions of ozone and nitrogen oxides with TransCut are significantly fewer than with air-based plasma cutting processes. For stainless steels the amount of chrome and nickel vapours is also reduced. Most importantly, the huge reduction in dust pollution significantly improves the workplace climate.

A light, compact and mobile device is all that is required for TransCut plasma cutting. Because it simply needs to be connected to a 230 V socket, and the integral tank needs filling only rarely, you can rest assured that the device will be available at all times. Moreover, in comparison with conventional plasma cutting methods, smaller quantities of pollutants are produced, and the cutting results are also superior.